The Ultimate Guide To CBN Inserts: Everything You Need To Know

Welcome to the ultimate guide to CBN inserts! If you are in the market for cutting-edge machining tools or simply curious about the latest advancements in the industry, you have come to the right place. In this comprehensive article, we cover everything you need to know about CBN inserts, from their composition and benefits to their applications and maintenance. Join us as we delve into the world of CBN inserts and discover why they are revolutionizing the manufacturing landscape.

- Introduction to CBN Inserts

CBN inserts are an essential tool in the world of machining and cutting, offering superior performance and durability compared to traditional inserts. In this comprehensive guide, we will delve into the intricacies of CBN inserts and everything you need to know about them.

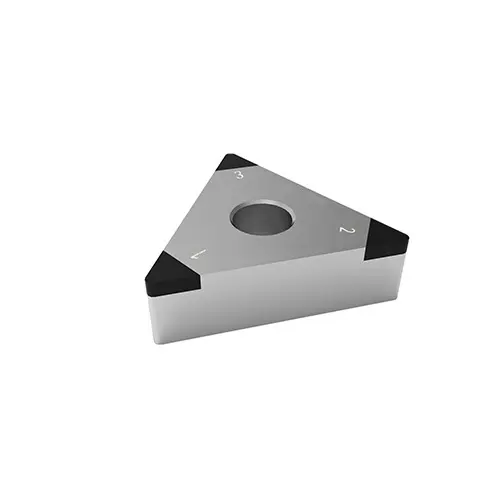

To begin with, let's define what CBN inserts are. CBN, or cubic boron nitride, is a synthetic material that is second only to diamond in hardness. This makes CBN inserts ideal for cutting hard materials such as hardened steel, cast iron, and superalloys. CBN inserts are comprised of a CBN tip that is brazed onto a carbide substrate, providing the perfect combination of hardness and toughness.

One of the key advantages of CBN inserts is their longevity. With a hardness that is much higher than traditional carbide inserts, CBN inserts can last up to five times longer, reducing tool changeovers and increasing productivity. This durability also leads to cost savings in the long run, as fewer inserts need to be replaced.

In addition to their longevity, CBN inserts also offer superior surface finish and dimensional accuracy. The sharp cutting edge and high thermal conductivity of CBN inserts result in smooth finishes and precise cuts, making them ideal for applications that require high precision.

Furthermore, CBN inserts are highly versatile and can be used in a wide range of machining operations. Whether you are cutting hard materials, high-temperature alloys, or abrasive composites, CBN inserts can handle the job with ease. They are also suitable for both roughing and finishing operations, making them a versatile tool for any machining process.

When it comes to choosing the right CBN insert for your application, there are several factors to consider. The type of material being cut, the cutting speed, the feed rate, and the depth of cut all play a role in determining the best insert for the job. It is important to consult with a knowledgeable supplier or manufacturer to ensure that you are using the right CBN insert for optimal performance.

In conclusion, CBN inserts are a game-changer in the world of machining and cutting. With their superior hardness, durability, and versatility, CBN inserts offer unmatched performance in a variety of applications. By understanding the ins and outs of CBN inserts and choosing the right tool for the job, you can achieve unparalleled results in your machining operations.

- Advantages of Using CBN Inserts

Cubic Boron Nitride (CBN) inserts are innovative cutting tools that offer a wide range of advantages in various machining applications. These inserts are made from synthetic diamonds, making them extremely hard and durable, which means they can withstand high temperatures and provide long-lasting performance. In this comprehensive guide, we will delve into the many advantages of using CBN inserts in your machining operations.

One of the key advantages of CBN inserts is their exceptional wear resistance. Unlike traditional cutting tools, CBN inserts can maintain their cutting edge for longer periods, resulting in increased productivity and cost savings. This wear resistance is particularly beneficial in high-speed machining operations or when working with abrasive materials.

In addition to wear resistance, CBN inserts also offer superior thermal conductivity. This means that they can effectively dissipate heat generated during the cutting process, reducing the risk of thermal damage to the workpiece and extending tool life. The ability to withstand high temperatures also allows CBN inserts to be used in applications where traditional cutting tools would fail.

Another advantage of CBN inserts is their versatility. These cutting tools can be used in a wide range of materials, including hardened steels, cast irons, and superalloys. Whether you are working with ferrous or non-ferrous metals, CBN inserts can provide excellent surface finishes and dimensional accuracy.

Furthermore, CBN inserts are known for their consistent performance. Unlike traditional cutting tools that may require frequent regrinding or replacement, CBN inserts maintain their sharpness and cutting efficiency over time. This consistency in performance ensures stable and predictable machining results.

Moreover, CBN inserts are easy to use and require minimal maintenance. With their long tool life and minimal downtime for tool changes, operators can focus on completing the machining process efficiently and effectively. Additionally, the high precision and accuracy of CBN inserts reduce the need for secondary operations, saving time and resources.

Overall, the advantages of using CBN inserts in machining operations are clear. From superior wear resistance and thermal conductivity to versatility and consistent performance, these cutting tools offer a range of benefits that can enhance productivity and quality in various applications. By incorporating CBN inserts into your machining processes, you can achieve cost savings, improved efficiency, and superior results. So, why not consider investing in CBN inserts for your machining needs?

- How to Select the Right CBN Insert for Your Application

When it comes to machining difficult-to-cut materials such as hardened steels, high-temperature alloys, and superalloys, CBN inserts are the go-to choice for many manufacturers in the industry. But with so many different types and grades of CBN inserts available on the market, selecting the right one for your specific application can be a daunting task. In this comprehensive guide, we will delve deep into the world of CBN inserts, covering everything you need to know to make an informed decision when selecting the right CBN insert for your application.

First and foremost, it is crucial to understand the basic properties of CBN inserts. CBN, or cubic boron nitride, is a synthetic material that is second only to diamond in terms of hardness. This makes CBN inserts highly resistant to wear and able to withstand high cutting temperatures, making them ideal for machining hard materials that would quickly wear out conventional carbide inserts.

There are several factors to consider when selecting the right CBN insert for your specific application. One of the most important considerations is the type of material you will be machining. Different grades of CBN inserts are designed to excel in different materials, so it is essential to choose an insert that is specifically suited to the material you will be working with.

Another important factor to consider is the geometry of the CBN insert. The geometry of the insert will determine the type of cutting operations it is best suited for, as well as its performance in terms of tool life and surface finish. Factors such as nose radius, cutting edge preparation, and chipbreaker design all play a role in determining the overall performance of the insert.

In addition to material and geometry considerations, it is also important to consider the coating on the CBN insert. Coatings can improve the wear resistance and thermal conductivity of the insert, extending its tool life and improving machining performance. Common coatings for CBN inserts include TiN, TiCN, and Al2O3, among others.

When selecting a CBN insert, it is also important to consider the specific requirements of your application, such as cutting speed, feed rate, and depth of cut. By matching the insert to these parameters, you can optimize cutting performance and maximize tool life.

In conclusion, selecting the right CBN insert for your application is a critical decision that can have a significant impact on machining performance and productivity. By considering factors such as material, geometry, coating, and application requirements, you can choose a CBN insert that will deliver exceptional results and help you achieve your machining goals. Remember, when it comes to CBN inserts, knowledge is power – so take the time to educate yourself and make an informed decision that will benefit your business in the long run.

- Tips for Proper Maintenance and Care of CBN Inserts

CBN inserts are a crucial tool in the manufacturing industry, known for their exceptional hardness and wear resistance. To ensure the longevity and efficiency of your CBN inserts, proper maintenance and care are essential. In this article, we will provide you with valuable tips on how to properly maintain and care for your CBN inserts.

One of the most important aspects of caring for your CBN inserts is to store them properly. It is crucial to keep them in a dry and clean environment to prevent any damage or corrosion. Make sure to store them in a protective case or container to avoid any potential accidents or mishandling.

Another important aspect of CBN insert maintenance is to regularly clean them after each use. This will help remove any built-up debris or residue that may hinder their performance. Use a soft brush or cloth to gently clean the inserts, making sure to not use any harsh chemicals that could damage the material.

Furthermore, it is important to inspect your CBN inserts regularly for any signs of wear or damage. Look out for any chipping, cracks, or dulling of the cutting edge. If you notice any of these signs, it is crucial to replace the insert immediately to prevent any further damage to your workpiece.

In addition to regular cleaning and inspection, it is also essential to properly lubricate your CBN inserts. This will help reduce friction and heat generation during cutting, ultimately prolonging the life of the insert. Use a high-quality lubricant specifically designed for CBN inserts to ensure optimal performance.

When using CBN inserts, it is important to follow the manufacturer's guidelines and recommendations for proper usage. Make sure to use the correct cutting parameters, such as cutting speed, feed rate, and depth of cut, to ensure optimal performance and longevity of your inserts.

In conclusion, proper maintenance and care of your CBN inserts are crucial for ensuring their longevity and efficiency. By following the tips outlined in this article, you can prolong the life of your inserts and achieve the best results in your manufacturing processes. Remember to store them properly, clean them regularly, inspect for wear, lubricate appropriately, and follow manufacturer guidelines for optimal performance. With these tips, you can ensure that your CBN inserts remain in top condition for all your cutting needs.

- Common FAQs about CBN Inserts

If you are in the world of machining, chances are you have heard about CBN inserts. CBN inserts are a popular choice for many machining applications due to their durability and versatility. In this ultimate guide to CBN inserts, we will explore everything you need to know about these essential tools, focusing on common FAQs about CBN inserts.

What are CBN inserts?

CBN inserts are cutting tools that are made from cubic boron nitride (CBN), a synthetic material that is second only to diamond in terms of hardness. CBN inserts are designed to provide high levels of precision and efficiency in machining applications, making them a popular choice for a wide range of industries.

What are the benefits of using CBN inserts?

One of the main benefits of using CBN inserts is their durability. CBN is a highly wear-resistant material, meaning that CBN inserts can last much longer than traditional cutting tools. This can help to reduce tooling costs and increase efficiency in machining operations. Additionally, CBN inserts are known for their high thermal conductivity, which helps to dissipate heat during cutting and prevent tool wear.

What are the different types of CBN inserts?

There are several different types of CBN inserts available, each designed for specific machining applications. Some common types of CBN inserts include tipped inserts, solid inserts, and wiper inserts. Tipped inserts feature a CBN tip that is brazed onto a carbide substrate, while solid inserts are made entirely of CBN material. Wiper inserts have a special geometry that helps to improve surface finish and reduce cutting forces.

What materials can CBN inserts cut?

CBN inserts are capable of machining a wide range of materials, including hardened steels, cast irons, and superalloys. CBN inserts are especially well-suited for machining materials that are difficult to cut with traditional cutting tools, such as hardened steel and high-temperature alloys. This makes CBN inserts a versatile choice for many different machining applications.

How can I achieve the best results with CBN inserts?

To achieve the best results with CBN inserts, it is important to use the right cutting parameters and machining strategies. It is also essential to ensure that the workpiece material is properly secured and that the cutting tool is properly aligned. Additionally, regular maintenance and inspection of CBN inserts is crucial to ensuring optimal performance and longevity.

In conclusion, CBN inserts are an essential tool for many machining applications, thanks to their durability, versatility, and efficiency. By understanding the common FAQs about CBN inserts and following best practices for using these cutting tools, you can achieve superior results in your machining operations. Whether you are working with hardened steels, cast irons, or superalloys, CBN inserts can help you achieve precision and efficiency in your machining processes.

Conclusion

In conclusion, CBN inserts have revolutionized the machining industry with their exceptional hardness, thermal conductivity, and wear resistance properties. By understanding the different grades, shapes, and applications of CBN inserts, manufacturers can make informed decisions to optimize their machining processes and achieve superior results. Whether you are machining hardened steels, cast irons, or superalloys, CBN inserts offer a reliable and efficient solution to meet your cutting needs. With the knowledge gained from this ultimate guide, you are now equipped to harness the power of CBN inserts and elevate your machining capabilities to new heights. So, start exploring the world of CBN inserts and unlock the potential for unparalleled precision and productivity in your machining operations.