Maximizing Efficiency With PCBN Inserts: A Game-Changer In Machining Technology

Are you ready to revolutionize your machining operations and take efficiency to a whole new level? Look no further than PCBN inserts – the game-changer in machining technology. In this article, we'll explore how these powerful tools can transform your manufacturing processes and help you maximize productivity like never before. Join us as we dive into the world of PCBN inserts and discover the key to unlocking peak efficiency in your operations.

- Introduction to PCBN Inserts

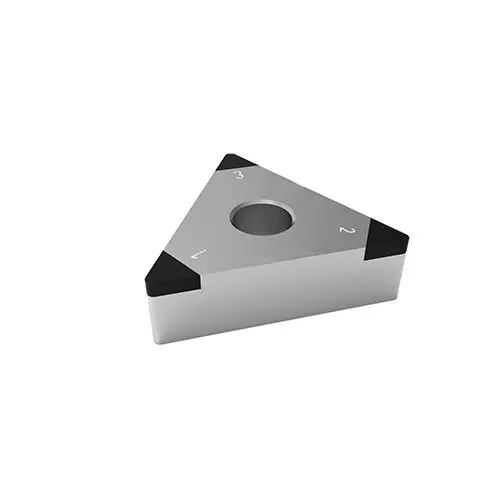

PCBN inserts, or Polycrystalline Cubic Boron Nitride inserts, have revolutionized the machining industry with their superior performance and efficiency. In this introduction to PCBN inserts, we will explore the benefits and applications of this game-changing tool in machining technology.

PCBN inserts are made from a synthetic material that is second only to diamond in hardness, making them ideal for machining hard materials such as hardened steel, cast iron, and high-temperature alloys. These inserts offer exceptional wear resistance and thermal conductivity, allowing for higher cutting speeds and improved tool life.

One of the key advantages of PCBN inserts is their ability to reduce machining time and increase productivity. With their high cutting speeds and precision, manufacturers can achieve higher machining efficiency and lower production costs. This is especially beneficial for industries that require high-volume production or tight tolerances.

Furthermore, PCBN inserts produce superior surface finishes and dimensional accuracy, eliminating the need for secondary finishing operations. This not only saves time and resources but also ensures a consistent quality of the machined parts. In addition, PCBN inserts generate less heat during machining, resulting in reduced tool wear and extended tool life.

Another important advantage of PCBN inserts is their versatility in a wide range of machining applications. From turning and milling to grooving and threading, these inserts can handle various operations with ease. Whether it's automotive parts, aerospace components, or tool and die making, PCBN inserts deliver exceptional performance and precision.

In conclusion, PCBN inserts have become a game-changer in machining technology, offering unparalleled efficiency and performance. Their ability to reduce machining time, improve productivity, and produce high-quality machined parts makes them an essential tool for manufacturers looking to stay competitive in today's fast-paced industry. With their advanced capabilities and versatility, PCBN inserts are set to shape the future of machining technology for years to come.

- Advantages of Using PCBN Inserts in Machining

PCBN inserts, or polycrystalline cubic boron nitride inserts, are revolutionizing the machining industry with their superior performance and efficiency. These cutting-edge tools are a game-changer in machining technology, offering a multitude of advantages over traditional cutting inserts. From increased productivity to extended tool life, PCBN inserts are quickly becoming the go-to choice for manufacturers looking to maximize efficiency in their machining processes.

One of the key advantages of using PCBN inserts in machining is their exceptional hardness and wear resistance. Unlike traditional cutting inserts made of carbide or ceramic materials, PCBN inserts are composed of superhard cubic boron nitride particles embedded in a metallic binder. This unique composition gives PCBN inserts a hardness second only to diamond, allowing them to withstand high temperatures and extreme machining conditions without losing their cutting edge.

The superior hardness and wear resistance of PCBN inserts translate into longer tool life and reduced downtime for manufacturers. With PCBN inserts, machining operations can run for extended periods without the need for frequent tool changes, resulting in increased productivity and cost savings. Additionally, the wear resistance of PCBN inserts means that they can maintain their cutting edge sharpness for longer, ensuring consistent and high-quality machining results.

In addition to their exceptional durability, PCBN inserts also offer superior thermal conductivity, which helps to dissipate heat generated during machining. This thermal stability allows for higher cutting speeds and feeds, leading to faster material removal rates and increased efficiency in the machining process. With PCBN inserts, manufacturers can achieve higher levels of productivity and meet tight production deadlines with ease.

Furthermore, the versatility of PCBN inserts makes them suitable for a wide range of machining applications, including turning, milling, and boring. Whether machining hardened steels, cast irons, or superalloys, PCBN inserts deliver consistent and reliable performance across a variety of materials. Their ability to maintain sharp cutting edges and withstand high cutting forces makes them an ideal choice for complex machining operations that require precision and accuracy.

Overall, the advantages of using PCBN inserts in machining are clear. Their exceptional hardness, wear resistance, thermal conductivity, and versatility make them a valuable asset for manufacturers looking to maximize efficiency and productivity in their machining processes. With PCBN inserts, manufacturers can achieve higher cutting speeds, longer tool life, and superior machining results, ultimately leading to cost savings and increased competitiveness in the market.

- Case Studies: Success Stories of Maximizing Efficiency with PCBN Inserts

PCBN inserts stand for Polycrystalline Cubic Boron Nitride inserts and are a game-changer in machining technology. These inserts are known for their superior hardness and wear resistance, making them an ideal choice for cutting materials that are traditionally difficult to machine, such as hardened steels and superalloys.

One of the key advantages of PCBN inserts is their ability to maximize efficiency in machining operations. By using PCBN inserts, manufacturers can achieve higher cutting speeds, longer tool life, and improved surface finishes. These inserts are also known for their chip control abilities, reducing the risk of tool breakage and improving overall process stability.

To illustrate the success stories of maximizing efficiency with PCBN inserts, let’s take a look at some case studies from various industries:

1. Aerospace Industry: A leading aerospace manufacturer was experiencing challenges in machining titanium alloys, which are known for their high strength and heat resistance. By switching to PCBN inserts, the manufacturer was able to increase cutting speeds by 30% and triple the tool life. This not only resulted in cost savings but also improved overall productivity.

2. Automotive Industry: An automotive supplier was facing difficulties in machining hardened steel components for engine parts. After implementing PCBN inserts, the supplier witnessed a significant reduction in cycle times and a 40% increase in tool life. This allowed them to meet tight production deadlines and deliver high-quality components to their customers.

3. Oil and Gas Industry: A oil and gas company specializing in drilling equipment needed a solution to improve the efficiency of their machining operations for stainless steel components. By using PCBN inserts, the company was able to achieve a 50% increase in cutting speeds and a 60% improvement in surface finish. This enabled them to produce components with tighter tolerances and enhance their competitive edge in the industry.

Overall, these case studies demonstrate the transformative impact of PCBN inserts in optimizing machining processes and maximizing efficiency. By leveraging the superior properties of PCBN inserts, manufacturers across industries can achieve significant cost savings, improve product quality, and boost overall productivity. As technology continues to evolve, PCBN inserts will remain a cornerstone in the advancement of machining technology, offering endless possibilities for innovation and success.

- Tips for Implementing PCBN Inserts in Machining Operations

PCBN inserts, short for polycrystalline cubic boron nitride inserts, have revolutionized the world of machining technology. These cutting-edge tools are known for their exceptional durability, wear resistance, and thermal stability, making them a game-changer in precision machining operations. In this article, we will delve into the world of PCBN inserts and provide tips for implementing them effectively in your machining operations.

The first key aspect to consider when using PCBN inserts is understanding their composition and properties. PCBN inserts are made from synthetic diamonds, which are the hardest material known to man, making them ideal for cutting tough materials like hardened steels, cast irons, and superalloys. Additionally, PCBN inserts have excellent thermal stability, which means they can withstand high temperatures generated during machining without losing their cutting edge. This makes them perfect for high-speed cutting operations where heat buildup is a common issue.

When it comes to implementing PCBN inserts in your machining operations, proper tool selection is crucial. It is essential to choose the right type of PCBN insert for the specific material and cutting conditions you are working with. For example, some PCBN inserts are designed for roughing operations, while others are better suited for finishing or semi-finishing. Additionally, consider the geometry of the insert, including the rake angle, clearance angle, and cutting edge radius, to ensure optimal cutting performance.

In addition to selecting the right PCBN insert, it is also important to pay attention to the cutting parameters, such as cutting speed, feed rate, and depth of cut. PCBN inserts are capable of achieving higher cutting speeds compared to traditional carbide inserts, so it is crucial to take advantage of this capability to maximize efficiency. However, it is important to balance cutting speed with feed rate and depth of cut to prevent premature wear or damage to the insert.

Furthermore, proper tool positioning and tool holding are essential for achieving accurate and consistent results with PCBN inserts. Make sure the insert is securely clamped in the tool holder and aligned properly with the workpiece to prevent vibrations or deflections during machining. Additionally, consider using coolant or lubricant to reduce heat buildup and prolong the life of the insert.

Lastly, regular maintenance and inspection of PCBN inserts are crucial for ensuring long-term performance and efficiency. Check the insert for signs of wear or damage, such as chipping or edge rounding, and replace it as needed to maintain cutting quality. Additionally, consider regrinding or re-coating the insert to extend its lifespan and reduce tooling costs.

In conclusion, PCBN inserts are a game-changer in machining technology, offering unparalleled durability, wear resistance, and thermal stability. By following the tips outlined in this article, you can maximize efficiency and productivity in your machining operations while achieving superior cutting performance with PCBN inserts.

- Future Trends in PCBN Inserts Technology

PCBN inserts, also known as polycrystalline cubic boron nitride inserts, are a cutting-edge technology that is revolutionizing the machining industry. These inserts are made from synthetic diamond particles bonded together under high pressure and temperature, resulting in a material that is incredibly hard and durable. This makes PCBN inserts ideal for cutting hard materials such as high-strength steels, cast irons, and superalloys.

One of the key advantages of using PCBN inserts is their longevity. Traditional cutting tools, such as carbide inserts, can wear out quickly when cutting hard materials, leading to frequent tool changes and downtime. PCBN inserts, on the other hand, have a much longer tool life, reducing the need for frequent replacements and increasing overall efficiency in the machining process.

Another benefit of PCBN inserts is their ability to maintain a sharp cutting edge for a longer period of time. This results in smoother surface finishes and improved dimensional accuracy in the final machined part. Additionally, PCBN inserts generate less heat during cutting, reducing the risk of thermal damage to the workpiece and extending tool life even further.

In addition to their durability and precision, PCBN inserts also offer increased machining speeds. The hardness of the material allows for higher cutting speeds without sacrificing tool life, resulting in faster cycle times and increased productivity. This improved efficiency can lead to cost savings for manufacturers and allow them to produce more parts in less time.

Looking towards the future, there are several trends in PCBN inserts technology that are shaping the industry. One key trend is the development of advanced coatings for PCBN inserts, which can further enhance their performance and increase their versatility in different machining applications. These coatings can improve chip control, reduce cutting forces, and enhance wear resistance, making PCBN inserts even more efficient and effective in a variety of cutting operations.

Another trend in PCBN inserts technology is the use of advanced manufacturing techniques, such as additive manufacturing, to create custom inserts tailored to specific machining needs. This customization allows for greater precision and optimization in cutting operations, resulting in even higher levels of efficiency and productivity.

Overall, PCBN inserts are a game-changer in machining technology, offering superior durability, precision, and efficiency compared to traditional cutting tools. As the industry continues to innovate and develop new technologies, the future of PCBN inserts looks bright, with endless possibilities for improving manufacturing processes and pushing the boundaries of what is possible in machining.

Conclusion

In conclusion, the use of PCBN inserts in machining technology has proven to be a game-changer in terms of maximizing efficiency and productivity. The superior hardness and wear resistance of PCBN inserts make them the ideal choice for cutting and machining tough materials like hardened steels, cast irons, and superalloys. By incorporating PCBN inserts into their machining processes, manufacturers can achieve higher cutting speeds, increased tool life, and improved surface finishes. Overall, PCBN inserts offer a cost-effective solution for achieving precision machining results and staying competitive in today's fast-paced manufacturing industry. Embracing this cutting-edge technology is sure to revolutionize machining operations and drive continued success for businesses looking to stay ahead of the curve.