PCBN Inserts Price: Factors To Consider

Are you currently in the market for PCBN inserts and are unsure of the factors to consider when it comes to their price? Look no further! In this article, we will explore the various factors that can affect the price of PCBN inserts. Whether you are a manufacturer or a buyer, understanding the key considerations in pricing will help you make informed decisions. Read on to learn more about PCBN inserts and the important factors to consider when it comes to their price.

PCBN Inserts Price: Factors to Consider

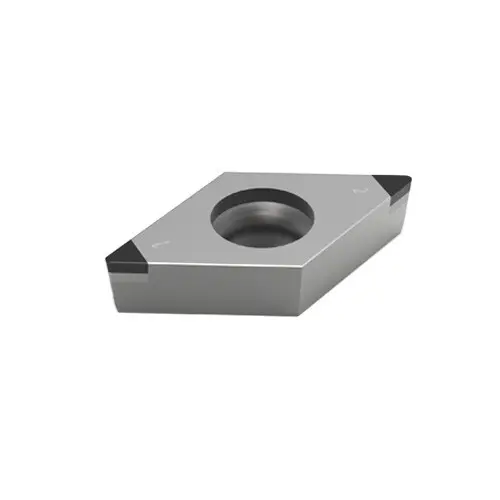

PCBN inserts, commonly known as Polycrystalline Cubic Boron Nitride inserts, are cutting tools used in the machining of various materials, including hardened steels, cast irons, and superalloys. These inserts are known for their high thermal conductivity, superior wear resistance, and ability to maintain sharp cutting edges, making them essential tools for precision machining operations.

When it comes to purchasing PCBN inserts, the price is a crucial factor to consider. However, there are several other important factors that should also be taken into account to ensure that you are getting the best value for your money. In this article, we will discuss the different factors to consider when evaluating the price of PCBN inserts.

Material Quality and Performance

The material quality and performance of PCBN inserts play a significant role in determining their price. Higher quality inserts, made from premium grade materials, are generally more expensive than their lower-quality counterparts. However, they offer superior performance, longer tool life, and better machining results, making them a worthwhile investment in the long run.

When considering the price of PCBN inserts, it is essential to assess the material quality and performance to ensure that you are getting inserts that are suitable for your specific machining requirements. Investing in high-quality PCBN inserts can result in improved productivity, reduced tooling costs, and higher machining efficiency.

Brand Reputation and Support

The reputation of the brand that manufactures the PCBN inserts is another factor to consider when evaluating their price. Established brands with a solid reputation for producing high-quality cutting tools often command a premium price for their products. However, this premium price is often justified by the brand's commitment to quality, extensive research and development, and ongoing support for their customers.

When purchasing PCBN inserts, it is advisable to choose a reputable brand with a proven track record of delivering reliable and high-performance cutting tools. Additionally, reputable brands often provide excellent customer support, technical assistance, and a comprehensive warranty, which can contribute to the overall value of the inserts.

Cost-Effectiveness and Long-Term Savings

While the initial price of PCBN inserts is an important consideration, it is crucial to take a broader view of their cost-effectiveness and long-term savings. High-quality PCBN inserts may have a higher upfront cost, but they can deliver significant long-term savings through extended tool life, reduced machining time, and improved surface finish.

When assessing the price of PCBN inserts, it is essential to consider their overall cost-effectiveness and the potential long-term savings they can offer. Investing in high-quality inserts that deliver consistent performance and durability can result in lower tooling costs, enhanced machining efficiency, and improved profitability for your business.

Customization and Specialized Requirements

Some machining operations may require specialized PCBN inserts with custom specifications to meet specific machining requirements. Customized inserts are often more expensive than standard off-the-shelf inserts due to the additional design, engineering, and manufacturing processes involved.

When evaluating the price of PCBN inserts, it is important to consider any customization or specialized requirements that may be necessary for your machining applications. While customized inserts may come at a higher price, they can provide tailored solutions that optimize machining performance and productivity, making them a worthwhile investment for certain applications.

Supplier and Service Capabilities

Finally, the capabilities of the supplier and the level of service they provide should be taken into consideration when evaluating the price of PCBN inserts. A reputable supplier with an extensive inventory, technical expertise, and responsive customer service can offer added value that justifies a slightly higher price for their products.

When purchasing PCBN inserts, it is important to partner with a reliable and knowledgeable supplier who can offer support, guidance, and timely delivery of the inserts. A trustworthy supplier can help you select the right inserts for your specific needs, provide technical assistance, and ensure that you are getting the best value for your investment.

In conclusion, when considering the price of PCBN inserts, it is essential to assess a range of factors beyond the initial cost. By evaluating the material quality, brand reputation, cost-effectiveness, customization options, and supplier capabilities, you can make an informed decision that provides the best value for your machining operations. Investing in high-quality PCBN inserts can lead to improved performance, reduced tooling costs, and enhanced profitability in the long run, making it a worthwhile investment for precision machining applications.

Conclusion

In conclusion, when considering the price of PCBN inserts, it is important to take into account the specific requirements of the machining application, the quality and durability of the inserts, and the reputation of the manufacturer. While price is an important factor, it should not be the sole consideration when making a decision. By carefully evaluating all the factors involved, manufacturers can make informed choices that will ultimately lead to improved efficiency, cost-effectiveness, and overall productivity in their machining operations. With the right PCBN inserts and a comprehensive understanding of the price factors, manufacturers can achieve outstanding results and stay competitive in the industry.