The Advantages Of Using PCBN Inserts In Machining Applications

Are you looking to improve your machining applications and enhance productivity? Look no further than PCBN inserts. In this article, we will explore the numerous advantages of using PCBN inserts in machining applications, from increased tool life to higher cutting speeds. Stay tuned to discover how incorporating PCBN inserts can revolutionize your machining process.

- Introduction to PCBN Inserts

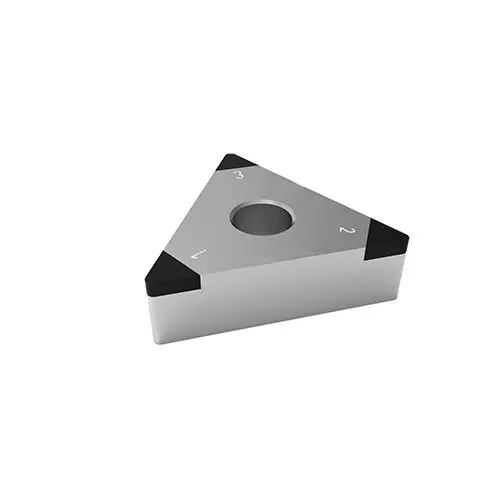

In the world of machining applications, PCBN inserts have become increasingly popular for their superior performance and increased efficiency compared to traditional cutting tools. PCBN, or polycrystalline cubic boron nitride, inserts are made from a synthetic material that is incredibly hard and wear-resistant, making them ideal for cutting and shaping tough materials like hardened steels, cast irons, and superalloys.

PCBN inserts are known for their longevity, with some inserts lasting up to ten times longer than traditional cutting tools. This extended tool life not only saves money on replacement costs but also reduces downtime for tool changes, increasing overall productivity in machining applications.

One of the key advantages of PCBN inserts is their ability to maintain sharp cutting edges even at high temperatures. This thermal stability allows for faster cutting speeds and feeds, resulting in quicker machining times and improved surface finishes. The high wear resistance of PCBN inserts also reduces the need for frequent tool changes, further increasing productivity.

In addition to their longevity and thermal stability, PCBN inserts also offer superior chip control and excellent surface finish quality. The precise cutting edges of PCBN inserts produce smoother surfaces and tighter tolerances, making them ideal for precision machining applications where accuracy is of the utmost importance.

PCBN inserts are also highly versatile, capable of handling a wide range of materials and machining processes. Whether cutting hardened steels in the aerospace industry or machining cast irons in the automotive industry, PCBN inserts can deliver consistent, high-quality results across a variety of applications.

Another advantage of using PCBN inserts is their environmental friendliness. Due to their long tool life and reduced need for additional cutting fluids, PCBN inserts contribute to a more sustainable machining process by reducing waste and minimizing environmental impact.

Overall, the benefits of using PCBN inserts in machining applications are clear. From increased productivity and efficiency to superior performance and environmental friendliness, PCBN inserts offer a cost-effective solution for achieving high-quality results in a variety of machining processes. With their exceptional hardness, thermal stability, and versatility, PCBN inserts are revolutionizing the way we approach cutting and shaping materials in the manufacturing industry.

- Cost and Time Savings in Machining Applications

PCBN inserts, also known as polycrystalline cubic boron nitride inserts, are cutting tools that have revolutionized machining applications due to their numerous advantages. One of the key benefits of using PCBN inserts is the significant cost and time savings they offer in machining applications. In this article, we will explore how PCBN inserts provide these advantages and why they are a superior choice for manufacturers looking to enhance productivity and efficiency.

PCBN inserts are made from a composite material of cubic boron nitride particles bonded together under high pressure and temperature. This material is exceptionally hard and wear-resistant, making it perfect for cutting operations that involve difficult-to-machine materials such as hardened steels, cast iron, and superalloys. Unlike traditional cutting tools like carbide inserts, PCBN inserts can withstand higher cutting speeds and feeds, resulting in faster machining times and increased productivity.

One of the main reasons why PCBN inserts lead to cost savings in machining applications is their extended tool life. Due to their exceptional hardness and wear resistance, PCBN inserts can last significantly longer than carbide inserts, minimizing the need for frequent tool changes and reducing downtime. This prolonged tool life not only reduces tooling costs but also translates into increased machine utilization and higher overall efficiency in the production process.

Furthermore, the use of PCBN inserts can also result in lower overall machining costs. By enabling faster cutting speeds and feeds, PCBN inserts help reduce cycle times and improve material removal rates, leading to a more efficient machining process. This increased efficiency means that manufacturers can produce more parts in less time, ultimately lowering the cost per part and improving the overall profitability of their operations.

In addition to cost savings, PCBN inserts also offer time savings in machining applications. With their ability to cut at higher speeds and feeds, PCBN inserts help streamline the machining process and reduce the time required to complete a job. This not only increases productivity but also allows manufacturers to meet tight production deadlines and respond quickly to changing customer demands.

Overall, the advantages of using PCBN inserts in machining applications are clear. From cost savings to time savings, PCBN inserts provide numerous benefits that can help manufacturers improve their competitiveness and drive growth in their businesses. By investing in high-quality PCBN inserts and implementing them effectively in their machining operations, manufacturers can achieve significant improvements in efficiency, productivity, and profitability.

- Superior Performance and Durability of PCBN Inserts

PCBN inserts, also known as polycrystalline cubic boron nitride inserts, are gaining popularity in machining applications due to their superior performance and durability. These cutting tools are made up of a layer of polycrystalline cubic boron nitride bonded to a carbide substrate, providing exceptional hardness and wear resistance. In this article, we will explore the advantages of using PCBN inserts in machining applications, focusing on their superior performance and durability.

One of the key advantages of PCBN inserts is their exceptional hardness. Polycrystalline cubic boron nitride is one of the hardest materials known, second only to diamond. This hardness allows PCBN inserts to maintain their cutting edges even when machining hard materials like hardened steels, cast irons, and superalloys. As a result, PCBN inserts can achieve higher cutting speeds and feed rates, leading to increased productivity and efficiency in machining operations.

In addition to their hardness, PCBN inserts also offer superior wear resistance. The unique composition of polycrystalline cubic boron nitride allows these inserts to withstand high temperatures and harsh machining conditions without losing their cutting edge. This translates to longer tool life and reduced tool changes, saving time and money for machining operations. Furthermore, the wear resistance of PCBN inserts helps improve the surface finish of machined parts, reducing the need for secondary finishing operations.

Another advantage of PCBN inserts is their thermal stability. Polycrystalline cubic boron nitride has excellent thermal conductivity, which helps dissipate heat during machining, preventing tool overheating and extending tool life. This thermal stability also allows PCBN inserts to be used in high-speed machining applications, where heat generation is a common challenge. By maintaining consistent cutting performance at elevated temperatures, PCBN inserts contribute to consistent quality and accuracy in machining operations.

Furthermore, PCBN inserts are versatile tools that can be used for a wide range of machining applications. From turning and milling to threading and grooving, PCBN inserts excel in various cutting operations across different industries. Whether machining ferrous or non-ferrous materials, PCBN inserts deliver reliable performance and excellent chip control, making them a preferred choice for manufacturers seeking high precision and efficiency.

In conclusion, the advantages of using PCBN inserts in machining applications are clear. With their superior performance, durability, hardness, wear resistance, thermal stability, and versatility, PCBN inserts are becoming indispensable tools for modern machining operations. By investing in PCBN inserts, manufacturers can enhance their productivity, improve their machining capabilities, and achieve superior results in their manufacturing processes.

- Increased Productivity and Efficiency in Machining Processes

PCBN inserts, also known as polycrystalline cubic boron nitride inserts, have revolutionized machining applications in various industries. These inserts are made of industrial-grade synthetic material, which has high thermal conductivity and exceptional hardness, making them ideal for cutting and shaping hard materials like hardened steels, cast irons, and superalloys. In this article, we will explore the advantages of using PCBN inserts in machining processes, focusing on increased productivity and efficiency.

One of the key benefits of using PCBN inserts in machining applications is their high wear resistance. Unlike traditional carbide inserts, PCBN inserts can withstand higher cutting temperatures, speeds, and feed rates without losing their cutting edge. This means that operators can achieve longer tool life and reduced downtime for tool changes, resulting in increased productivity and efficiency in machining processes.

Moreover, PCBN inserts offer superior surface finish on machined components. The ultra-hard material and precision manufacturing of PCBN inserts ensure that the machined surfaces are smooth and precise, eliminating the need for secondary finishing operations. This not only saves time but also improves the overall quality of the finished products, leading to increased customer satisfaction.

Furthermore, PCBN inserts are highly versatile and can be used in a wide range of machining applications, including turning, milling, boring, and grooving. Their exceptional performance in cutting hard materials makes them suitable for industries such as automotive, aerospace, oil and gas, and defense, where high precision and reliability are essential. By using PCBN inserts, manufacturers can achieve tighter tolerances, faster production cycles, and lower production costs.

In addition, the use of PCBN inserts promotes sustainable machining practices. The longer tool life of PCBN inserts means fewer inserts are needed over time, reducing tool consumption and waste. This not only benefits the environment but also contributes to cost savings for companies in the long run. Furthermore, the improved productivity and efficiency offered by PCBN inserts enable manufacturers to meet increasing demand and stay competitive in today's fast-paced market.

Overall, the advantages of using PCBN inserts in machining applications are clear. From increased productivity and efficiency to superior surface finish and sustainability, PCBN inserts offer a cost-effective and reliable solution for manufacturers looking to optimize their machining processes. By incorporating PCBN inserts into their operations, companies can enhance their competitiveness, meet customer demands, and drive innovation in the industry.

- Conclusion: The Impact of PCBN Inserts on Machining Applications

Polycrystalline cubic boron nitride (PCBN) inserts have revolutionized the field of machining applications with their unparalleled advantages and impact on precision cutting processes. The use of PCBN inserts has significantly improved the efficiency and quality of machining operations, leading to enhanced productivity and cost savings for industries across the globe.

One of the key advantages of using PCBN inserts in machining applications is their exceptional hardness and wear resistance. Unlike traditional cutting tools, PCBN inserts are capable of withstanding extreme temperatures and pressures, making them ideal for high-speed machining operations. This robustness not only improves tool life but also ensures consistent performance, resulting in superior surface finish and dimensional accuracy of machined parts.

Moreover, PCBN inserts exhibit excellent thermal conductivity, which allows for effective heat dissipation during cutting processes. This feature is crucial in preventing tool wear and prolonging tool life, thereby reducing production downtime and maintenance costs. Additionally, the high thermal stability of PCBN inserts enables them to maintain their cutting edge sharpness even in the most demanding machining conditions, ensuring consistent and reliable performance over an extended period.

Furthermore, PCBN inserts offer superior chemical inertness, making them resistant to chemical wear and corrosion. This property is particularly advantageous in machining applications that involve cutting abrasive or hard materials, as it enhances the overall durability and longevity of the tool. The resistance to chemical wear also minimizes the risk of built-up edge formation and chip adhesion, resulting in improved chip control and surface finish quality.

In addition, PCBN inserts are highly versatile and can be used in a wide range of machining applications, including turning, milling, drilling, and grooving. Their compatibility with various workpiece materials, such as hardened steels, cast irons, and superalloys, makes them an invaluable asset in the manufacturing industry. Whether in aerospace, automotive, or tooling industries, the use of PCBN inserts has proven to be instrumental in achieving precise and efficient machining operations.

Overall, the impact of PCBN inserts on machining applications is undeniable. Their unique combination of hardness, wear resistance, thermal conductivity, and chemical inertness sets them apart as the preferred choice for high-performance cutting tools. By incorporating PCBN inserts into their machining processes, industries can improve productivity, enhance product quality, and optimize production costs. As technology continues to advance, the role of PCBN inserts in shaping the future of machining applications will only become more significant.

Conclusion

In conclusion, the advantages of using PCBN inserts in machining applications cannot be overstated. From improved cutting speed and tool life to reduced downtime and increased productivity, PCBN inserts offer a range of benefits that can greatly enhance machining processes. By choosing PCBN inserts, manufacturers can expect higher quality results, enhanced efficiency, and ultimately, a competitive edge in the industry. As technology continues to evolve, investing in PCBN inserts is a smart choice for any organization looking to optimize their machining operations and stay ahead of the curve. Experience the advantages of PCBN inserts for yourself and take your machining applications to the next level.