The Ultimate Guide To Understanding PCBN Inserts In Machining

Are you looking to take your machining skills to the next level? Look no further than our comprehensive guide on PCBN inserts. In this ultimate guide, we break down everything you need to know about PCBN inserts and how they can revolutionize your machining processes. Whether you're a seasoned professional or just starting out, this article will provide invaluable insights and tips to help you optimize your machining operations. Dive into the world of PCBN inserts and unlock the potential for superior precision and performance in your shop.

- An Introduction to PCBN Inserts in Machining

PCBN inserts, short for polycrystalline cubic boron nitride inserts, are a critical component in the world of machining. These innovative tools are designed to enhance the efficiency, precision, and longevity of machining processes, making them indispensable for manufacturers seeking to optimize their production capabilities.

One of the primary advantages of PCBN inserts is their exceptional hardness and resistance to wear. Unlike traditional carbide inserts, which may wear down quickly when cutting tough materials like hardened steels or high-temperature alloys, PCBN inserts are specifically engineered to withstand the most demanding machining applications. This durability not only extends the tool's lifespan but also ensures consistent cutting performance over time.

Furthermore, PCBN inserts offer superior thermal conductivity, making them well-suited for high-speed cutting operations. The ability to dissipate heat effectively helps prevent tool wear and prolongs the tool's overall lifespan. This thermal stability also enables PCBN inserts to maintain their cutting edge integrity, resulting in higher machining accuracy and surface finish quality.

In addition to their exceptional hardness and thermal conductivity, PCBN inserts are also known for their versatility. These inserts can be used in a wide range of machining applications, from turning and milling to threading and grooving. Whether you are working with ferrous metals, non-ferrous materials, or heat-resistant alloys, PCBN inserts can provide the precision and reliability necessary to achieve optimal results.

Another key benefit of PCBN inserts is their cost-effectiveness in the long run. While these inserts may have a higher upfront cost compared to traditional cutting tools, their extended lifespan and superior performance ultimately translate into savings for manufacturers. By reducing tool changeovers, minimizing downtime, and improving overall machining efficiency, PCBN inserts offer a compelling return on investment for businesses looking to streamline their operations.

When it comes to selecting the right PCBN inserts for your specific machining needs, there are several factors to consider. These include the type of material being machined, the desired cutting parameters, and the overall machining strategy. With a thorough understanding of these variables, manufacturers can choose PCBN inserts that are tailored to their unique requirements, ensuring optimal performance and productivity.

In conclusion, PCBN inserts represent a game-changing technology in the field of machining, offering a host of benefits that can significantly enhance production processes. From their exceptional hardness and thermal conductivity to their versatility and cost-effectiveness, PCBN inserts have earned their reputation as indispensable tools for modern manufacturers. By incorporating these innovative inserts into their machining operations, businesses can unlock new levels of efficiency, precision, and profitability.

- The Benefits of Using PCBN Inserts for Machining

PCBN inserts, also known as polycrystalline cubic boron nitride inserts, have become increasingly popular in the world of machining due to their numerous benefits. These inserts are made of synthetic diamonds that are bonded to a carbide substrate, making them incredibly durable and efficient tools for cutting and machining hard materials. In this article, we will delve into the many advantages of using PCBN inserts in machining.

One of the main benefits of PCBN inserts is their exceptional hardness and abrasion resistance. Unlike traditional cutting tools, PCBN inserts can withstand high temperatures and pressures without losing their sharpness. This makes them ideal for machining hard materials such as hardened steels, cast irons, and superalloys. The hardness of PCBN inserts also ensures a longer tool life, reducing the need for frequent tool changes and improving overall productivity.

Another advantage of using PCBN inserts is their superior thermal conductivity. This property allows for efficient heat dissipation during the machining process, preventing the workpiece from overheating and reducing the risk of thermal damage. Additionally, the high thermal stability of PCBN inserts ensures consistent cutting performance, resulting in high-quality surface finishes and dimensional accuracy.

In addition to their hardness and thermal conductivity, PCBN inserts also offer excellent chemical stability. This means that they are resistant to chemical reactions with the workpiece material, prolonging their durability and performance. The chemical stability of PCBN inserts also makes them suitable for a wide range of machining applications, including turning, milling, and boring.

Furthermore, PCBN inserts are known for their versatility and adaptability. These inserts come in a variety of shapes, sizes, and grades to suit different machining requirements. Whether you are working on roughing, finishing, or precision machining, there is a PCBN insert available to meet your needs. Additionally, PCBN inserts can be easily reconditioned and re-tipped, extending their useful life and reducing tooling costs.

Overall, the benefits of using PCBN inserts in machining are clear. With their exceptional hardness, thermal conductivity, chemical stability, and versatility, PCBN inserts offer superior performance, cost-effectiveness, and efficiency compared to traditional cutting tools. By incorporating PCBN inserts into your machining processes, you can achieve higher productivity, improved surface finishes, and enhanced machining capabilities. Invest in PCBN inserts today and experience the ultimate guide to understanding their importance in the world of machining.

- How to Select the Right PCBN Inserts for Your Machining Needs

PCBN (Polycrystalline Cubic Boron Nitride) inserts are an essential tool in the field of machining. These inserts are widely used to provide efficient cutting solutions for hardened steels, cast irons, and superalloys. However, with the market flooded with various options, it can be overwhelming to select the right PCBN inserts for your machining needs. In this comprehensive guide, we will discuss the various factors to consider when choosing PCBN inserts, ensuring optimal performance and cost-effectiveness in your machining operations.

The first factor to consider is the material being machined. PCBN inserts are specifically designed to withstand the extreme hardness and high cutting temperatures produced during the machining process. Different PCBN grades have varying levels of hardness and thermal stability. For example, PCBN inserts with higher CBN content and a fine grain structure are ideal for roughing and interrupted cutting of hardened steels and cast irons. On the other hand, PCBN inserts with low CBN content and coarse grain structure are suitable for finishing operations on superalloys.

Next, consider the type and conditions of the machining operation. Different machining processes require PCBN inserts with specific geometries and cutting edge preparations. For instance, if you are performing a roughing operation with higher material removal rates, inserts with large nose radii and strong cutting edges are preferred. Conversely, when carrying out finishing operations that require superior surface finishes, inserts with small nose radii and sharp cutting edges are recommended.

Another crucial aspect to consider is the cutting speed and feed rate. Higher cutting speeds and feed rates increase productivity but also generate higher cutting temperatures. PCBN inserts with excellent thermal conductivity are essential to dissipate heat efficiently and prevent insert wear and tool damage. Additionally, the chemical stability of the PCBN grade should be considered to avoid chemical reactions between the workpiece material and the insert.

It is also important to take into account the depth of cut and machining conditions. In deep cuts or interrupted cutting, insert breakage can be a common issue. Therefore, selecting inserts with high fracture toughness and resistance to chipping is essential. Furthermore, the wear resistance of the PCBN grade is crucial in maintaining consistent cutting performance and extending the tool life.

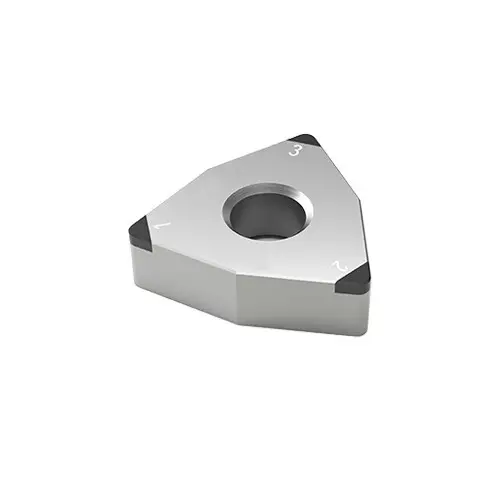

Additionally, consider the shape and size of the PCBN insert. The selection of insert shape is determined by the machined component's geometry and accessibility. Common insert shapes include round, square, triangle, and diamond. The size of the insert should match the machining center's tool holders or holders of other machine types, ensuring compatibility and efficient tool changes.

Lastly, budget considerations are important. PCBN inserts come in various price ranges depending on the grade, manufacturer, and supplier. It is crucial to strike a balance between quality and cost-effectiveness. Cheaper inserts may compromise on performance and tool life, leading to increased tool changeovers and decreased productivity in the long run. Therefore, investing in higher-quality PCBN inserts from reputable manufacturers is often a wise decision.

In conclusion, selecting the right PCBN inserts for your machining needs is a critical decision that can greatly impact the efficiency and effectiveness of your machining operations. By considering factors such as material being machined, type of machining operation, cutting speed, feed rate, depth of cut, and budget, you can ensure optimal performance and cost-effectiveness in your machining processes. Always consult with experienced tooling experts and manufacturers to assist you in making the best choice for your specific machining requirements.

- Tips for Maximizing the Performance of PCBN Inserts in Machining

Polycrystalline cubic boron nitride (PCBN) inserts are essential tools in CNC machining, offering high hardness and abrasion resistance for cutting hard materials such as hardened steel, cast iron, and high-temperature alloys. In order to fully harness the potential of PCBN inserts in machining, it is important to understand how to maximize their performance. In this comprehensive guide, we will provide tips and strategies for getting the most out of your PCBN inserts.

One of the key factors in optimizing the performance of PCBN inserts is selecting the right grade for the specific machining application. Different grades of PCBN inserts are designed to provide optimal performance in various materials and cutting conditions. For example, a high CBN content grade is suitable for machining materials with high hardness, while a tougher grade may be more effective for interrupted cuts or unstable machining conditions.

In addition to selecting the right grade, it is important to ensure proper tool geometry and cutting parameters for PCBN inserts. The cutting edge geometry, including the rake angle, clearance angle, and cutting edge radius, plays a crucial role in the cutting process. By carefully selecting the appropriate tool geometry, you can minimize cutting forces, reduce tool wear, and improve surface finish.

Furthermore, optimizing cutting parameters such as cutting speed, feed rate, and depth of cut can significantly impact the performance of PCBN inserts. Balancing these parameters to achieve the desired material removal rate while maintaining tool life and surface finish is essential for efficient machining with PCBN inserts.

Another important aspect of maximizing the performance of PCBN inserts is ensuring proper machine tool setup and rigidity. Vibrations and chatter during machining can lead to poor surface finish, tool wear, and reduced tool life. By using a stable and rigid machine tool setup, you can minimize these issues and improve the overall performance of PCBN inserts.

Regular maintenance and inspection of PCBN inserts are also crucial for optimizing their performance. Monitoring tool wear, examining chip formation, and checking for edge chipping can help you identify potential issues early on and take corrective actions to prevent premature tool failure.

In conclusion, understanding how to maximize the performance of PCBN inserts in machining involves a combination of selecting the right grade, optimizing tool geometry and cutting parameters, ensuring machine tool rigidity, and conducting regular maintenance and inspection. By following these tips and strategies, you can effectively utilize PCBN inserts to achieve high precision, quality, and efficiency in your machining operations.

- Case Studies: Successful Applications of PCBN Inserts in Machining

PCBN inserts, short for Polycrystalline Cubic Boron Nitride inserts, are cutting tools widely used in machining operations due to their superior hardness and wear resistance compared to traditional inserts. In this article, we will delve into the successful applications of PCBN inserts in machining through a series of case studies, demonstrating their efficacy and versatility in various machining processes.

One key application of PCBN inserts is in turning operations, where the inserts are used to machine hardened steels, cast irons, and superalloys. In a case study conducted by a renowned aerospace manufacturer, PCBN inserts were utilized to turn a workpiece made of Inconel 718, a high-strength, nickel-based superalloy commonly used in aerospace applications. The PCBN inserts demonstrated exceptional tool life and machining efficiency, resulting in significant cost savings for the manufacturer.

Another noteworthy case study involves the use of PCBN inserts in milling operations. A leading automotive component manufacturer implemented PCBN inserts in milling a hardened steel crankshaft, a critical component in engines that requires high precision and surface finish. The PCBN inserts not only delivered superior surface finish and dimensional accuracy but also exhibited extended tool life compared to conventional carbide inserts, enhancing the overall productivity of the machining process.

Furthermore, PCBN inserts have found widespread success in boring applications, particularly in the machining of cast iron engine blocks. In a case study conducted by a precision engineering company, PCBN inserts were employed to bore the cylinder bores of an engine block made of compacted graphite iron. The high abrasion resistance and thermal conductivity of the PCBN inserts allowed for faster cutting speeds and reduced cycle times, resulting in improved machining accuracy and surface quality.

In addition to turning, milling, and boring operations, PCBN inserts have also been successfully applied in threading, grooving, and parting-off processes. Their exceptional performance in these operations can be attributed to their high thermal stability, chemical inertness, and low coefficient of friction, making them ideal for machining a wide range of materials, including hardened steels, stainless steels, and heat-resistant alloys.

In conclusion, the successful applications of PCBN inserts in machining underscore their importance as indispensable cutting tools in modern manufacturing. The case studies highlighted in this article demonstrate the remarkable benefits of using PCBN inserts, including increased productivity, improved surface finish, and reduced tooling costs. As machining technologies continue to advance, PCBN inserts will undoubtedly play a crucial role in enhancing the efficiency and competitiveness of machining operations across various industries.

Conclusion

In conclusion, PCBN inserts are incredibly valuable tools in the world of machining, offering a range of benefits such as increased tool life, higher precision, and improved surface finish. By understanding the characteristics, applications, and advantages of PCBN inserts, machinists can optimize their processes and achieve higher efficiency and accuracy in their work. With the information provided in this ultimate guide, you are now equipped with the knowledge to make informed decisions when selecting and utilizing PCBN inserts in your machining operations. So, go ahead and integrate these powerful tools into your machining arsenal to take your productivity and performance to the next level. Happy machining!