Thread Cutting Inserts: Types And Applications

Welcome to our in-depth guide on thread cutting inserts and their various types and applications. Whether you are an experienced machinist looking to expand your knowledge or a novice searching for the right cutting insert for your project, this article is packed with valuable information to help you make informed decisions. From understanding the different types of thread cutting inserts to exploring their applications in various industries, we've got you covered. So, if you're ready to delve into the world of thread cutting inserts, read on to discover everything you need to know.

Thread Cutting Inserts: Types and Applications

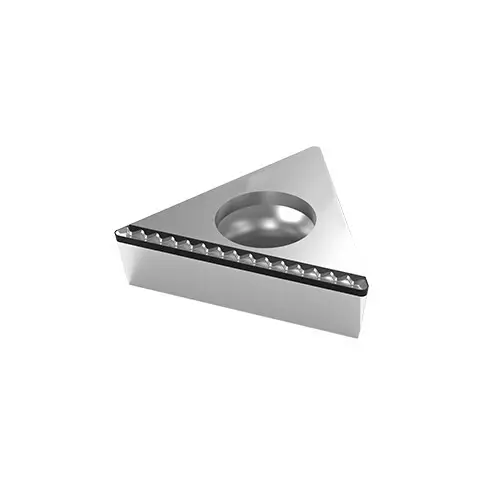

Thread cutting inserts are an essential tool in the manufacturing and metalworking industry. They are used to create threads on various materials including metals, plastics, and composites. With advancements in technology, there are several types of thread cutting inserts available in the market, each designed for specific applications and materials. In this article, we will explore the different types of thread cutting inserts and their applications in the industry.

Types of Thread Cutting Inserts

1. Single-point Inserts

Single-point thread cutting inserts are one of the most common types used in the industry. They have a single cutting point and are designed for producing internal and external threads. These inserts are versatile and can be used on a wide range of materials including aluminum, steel, and cast iron. Single-point inserts are known for their precision and are often used in high-precision applications.

2. Multi-point Inserts

Multi-point inserts, also known as multi-tooth inserts, have multiple cutting points. These inserts are designed for higher cutting speeds and are ideal for high-production environments. They are commonly used for creating fine threads on hard materials such as stainless steel and titanium. Multi-point inserts are known for their excellent chip control and are suitable for both internal and external threading operations.

3. Indexable Inserts

Indexable inserts are designed for easy replacement and repositioning. They are often used in CNC machining and turning operations. Indexable inserts come in different shapes and sizes and are suitable for a wide range of threading applications. These inserts are known for their cost-efficiency and are widely used in mass production.

4. Threading Inserts for Specific Materials

There are specialized threading inserts designed for specific materials such as aluminum, brass, and plastics. These inserts are optimized for the specific properties of the material, allowing for efficient and precise threading operations. For example, aluminum threading inserts are designed to prevent built-up edge and ensure a smooth finish on aluminum surfaces.

5. Coated Inserts

Coated inserts are designed to improve tool life and performance. These inserts are coated with materials such as titanium nitride (TiN), titanium carbonitride (TiCN), and aluminum titanium nitride (AlTiN) to enhance their wear resistance and prevent chip build-up. Coated inserts are ideal for high-speed machining and are suitable for a variety of materials including steel, stainless steel, and high-temperature alloys.

Applications of Thread Cutting Inserts

1. Automotive Industry

Thread cutting inserts are widely used in the automotive industry for producing threaded components such as engine parts, transmission components, and suspension components. Single-point inserts are commonly used for creating threads on aluminum and cast iron components, while coated inserts are preferred for machining high-strength steel components.

2. Aerospace Industry

In the aerospace industry, thread cutting inserts are used for creating precise threads on aircraft components such as landing gear, engine components, and structural elements. Multi-point inserts are often used for the high-speed machining of titanium and stainless steel components, ensuring high precision and surface finish.

3. Medical Industry

Thread cutting inserts play a critical role in the manufacturing of medical devices and implants. Specialized inserts for specific materials are used for creating threads on medical-grade titanium, stainless steel, and biocompatible polymers. The high precision and wear resistance of these inserts are essential for ensuring the quality and reliability of medical components.

4. Oil and Gas Industry

In the oil and gas industry, thread cutting inserts are used for creating threads on pipes, valves, and drilling components. Coated inserts are preferred for machining high-temperature alloys and corrosion-resistant materials commonly used in the industry. These inserts are designed to withstand the extreme conditions encountered in oil and gas applications.

5. General Manufacturing

Thread cutting inserts are extensively used in general manufacturing for producing a wide range of threaded components including fasteners, fittings, and machine parts. Indexable inserts are popular in this sector for their versatility and cost-efficiency. Various types of inserts are used depending on the material and threading requirements, ensuring efficient and reliable production.

Thread cutting inserts are essential tools for the manufacturing and metalworking industry, offering a wide range of options for creating threads on different materials. Understanding the types of inserts and their applications is crucial for selecting the right tool for the job and ensuring efficient and high-quality threading operations. Whether in the automotive, aerospace, medical, oil and gas, or general manufacturing industries, the right choice of thread cutting inserts can significantly impact the performance and productivity of machining operations.

Conclusion

In conclusion, thread cutting inserts play a vital role in the manufacturing industry, offering versatility and efficiency in creating high-quality threads. With various types of inserts available, including full form, partial form, and single-point inserts, manufacturers have the flexibility to choose the best tool for their specific threading needs. Whether it's creating internal or external threads, cutting threads on different materials, or achieving precise thread profiles, these inserts have proven to be invaluable in a wide range of applications. By understanding the different types and their applications, manufacturers can make informed decisions to optimize their threading processes and ultimately improve their overall production efficiency. As technology continues to advance, it will be interesting to see how thread cutting inserts evolve and continue to meet the demands of the growing manufacturing industry.