PCD Insert: Features And Machining Applications

Are you curious about the features and machining applications of PCD inserts? Look no further! In this article, we will delve into the world of PCD inserts, exploring their cutting-edge features and the wide range of applications they can be used for. Whether you're a seasoned professional or just starting out in the machining industry, this article is a must-read for anyone looking to expand their knowledge and understanding of PCD inserts. Join us as we explore the endless possibilities of this innovative tool and how it can revolutionize your machining processes.

PCD Insert: Features and Machining Applications

to PCD Inserts

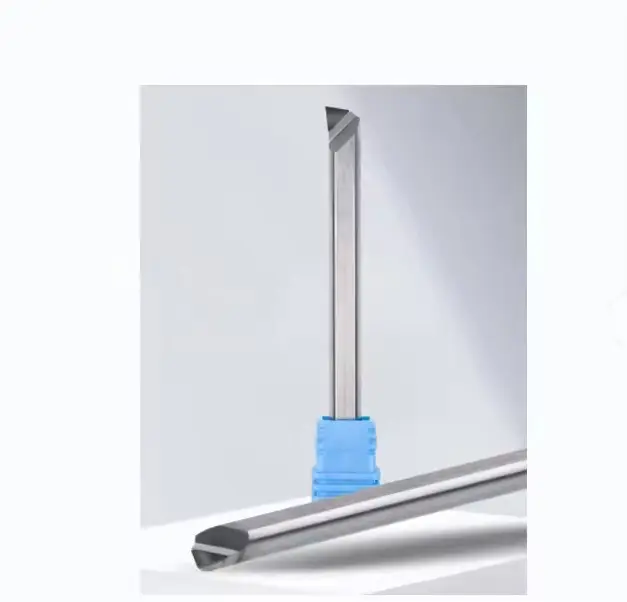

PCD inserts, short for Polycrystalline Diamond inserts, are cutting tools used in machining applications. These inserts are made of a layer of polycrystalline diamond, which is sintered onto a tungsten carbide substrate. PCD inserts are known for their exceptional hardness, thermal conductivity, and wear resistance, making them ideal for cutting and machining hard materials such as aluminum, copper, and non-ferrous alloys.

Features of PCD Inserts

1. Exceptional Hardness: The polycrystalline diamond layer on PCD inserts gives them extreme hardness, allowing them to withstand high temperatures and abrasion during machining operations. This makes them suitable for the most demanding machining applications.

2. High Thermal Conductivity: PCD inserts have excellent thermal conductivity, which helps in dissipating heat generated during high-speed cutting. This feature extends the tool life and ensures consistent and precise machining.

3. Superior Wear Resistance: The abrasion resistance of PCD inserts is significantly higher than that of traditional cutting tools. This enables them to maintain their sharp cutting edge for a longer period, resulting in improved productivity and reduced tooling costs.

4. Wide Range of Applications: PCD inserts are suitable for a variety of machining applications, including turning, milling, boring, and drilling. They are used in industries such as automotive, aerospace, and die and mold making.

5. Excellent Surface Finish: The superior cutting edge quality of PCD inserts results in an excellent surface finish on the workpiece, reducing the need for secondary finishing operations.

Machining Applications of PCD Inserts

1. Turning: PCD inserts are widely used in turning operations, especially for high-precision and high-speed machining of non-ferrous materials. They are capable of maintaining tight tolerances and producing high-quality surface finishes.

2. Milling: PCD inserts excel in milling applications, where they can efficiently machine complex contours and features on workpieces. The high chip control and reduced tool wear make them a preferred choice for milling operations.

3. Boring: PCD inserts offer exceptional performance in boring operations, providing superior hole quality and dimensional accuracy. They are suitable for machining a wide range of materials, including composites and abrasive non-ferrous alloys.

4. Drilling: PCD inserts are used for drilling operations, especially in the production of precision holes in aluminum and other non-ferrous materials. Their high wear resistance ensures long tool life and consistent performance.

5. Specialized Applications: In addition to standard machining operations, PCD inserts are also used in specialized applications such as gear cutting, reaming, and grooving, where high precision and surface finish are crucial.

Advantages of Using PCD Inserts from VeryCarbon

1. Exceptional Tool Performance: VeryCarbon's PCD inserts are designed to deliver exceptional tool performance, enabling users to achieve higher productivity and efficiency in their machining operations.

2. Customized Solutions: VeryCarbon offers customized PCD inserts to meet the specific requirements of customers. Whether it's a unique cutting application or a special workpiece material, VeryCarbon can provide tailored solutions to optimize machining processes.

3. Technical Support: The team at VeryCarbon provides expert technical support and guidance to help customers select the right PCD inserts for their applications. From tool selection to machining parameters, they offer comprehensive assistance to ensure the success of every cutting operation.

4. Quality and Reliability: VeryCarbon's PCD inserts are manufactured to the highest standards of quality and reliability, ensuring consistent performance and long tool life. Customers can trust in the durability and consistency of VeryCarbon's cutting tools.

5. Cost-Effective Solutions: By using VeryCarbon's PCD inserts, customers can benefit from cost-effective machining solutions that reduce tooling expenses, increase process efficiency, and improve overall manufacturing profitability.

PCD inserts from VeryCarbon are designed to meet the challenges of modern machining applications, providing exceptional hardness, thermal conductivity, wear resistance, and superior cutting performance. With a wide range of machining applications and customizable solutions, VeryCarbon's PCD inserts are the go-to choice for industries looking to optimize their cutting processes and achieve superior results. Talk to the experts at VeryCarbon today to learn more about how their PCD inserts can elevate your machining operations.

Conclusion

In conclusion, PCD inserts offer a wide range of features and benefits that make them a valuable tool in machining applications. Their exceptional hardness, thermal conductivity, and wear resistance make them ideal for cutting and finishing hard materials such as carbon composites, ceramics, and non-ferrous metals. With their ability to provide high-quality surface finishes and extended tool life, PCD inserts are a cost-effective solution for precision machining. Whether used in turning, milling, or drilling operations, PCD inserts continue to prove their worth in a variety of industrial applications. As technology continues to advance, PCD inserts will likely remain a critical component in the realm of machining and material processing.