A Guide To Carbide Insert Drills: The Ultimate Tool For Efficient Drilling

Are you looking to take your drilling to the next level? Look no further than carbide insert drills. In this comprehensive guide, we delve into the world of carbide insert drills and why they are the ultimate tool for efficient drilling. Whether you are a DIY enthusiast or a professional tradesperson, this article will provide you with the knowledge and insights you need to make informed decisions about your drilling tools. Join us as we explore the power and benefits of carbide insert drills and discover how they can revolutionize your drilling experience.

- Understanding the Basics of Carbide Insert Drills

A carbide insert drill is a powerful tool that is essential for efficient drilling in various industries. Understanding the basics of carbide insert drills is crucial for maximizing its performance and longevity. In this comprehensive guide, we will delve into the key components and functions of carbide insert drills, as well as provide tips on how to use them effectively.

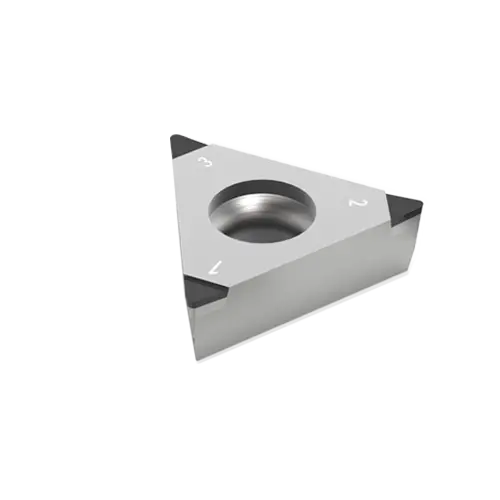

Carbide insert drills are machined tools with replaceable carbide inserts that are designed to withstand high temperatures and maintain sharp cutting edges. The carbide inserts are made from a combination of tungsten carbide and cobalt, making them extremely hard and durable. This allows carbide insert drills to cut through tough materials such as steel, stainless steel, and cast iron with ease.

One of the main advantages of carbide insert drills is their versatility. They can be used for various drilling applications, including drilling through holes, counterboring, countersinking, and reaming. This makes carbide insert drills the ultimate tool for a wide range of industries, from automotive to aerospace.

In order to maximize the performance of carbide insert drills, it is important to choose the right type of carbide insert for the specific drilling application. There are different types of carbide inserts available, each with unique geometries and coatings that are tailored for specific materials and cutting conditions. By selecting the right carbide insert, you can achieve superior cutting performance and extended tool life.

Additionally, proper maintenance is key to ensuring the longevity of carbide insert drills. Regularly inspecting the carbide inserts for wear and damage, as well as cleaning and lubricating the tool, can help prevent premature tool failure and optimize cutting performance. It is also important to follow the manufacturer's recommendations for speed and feed rates to prevent overheating and excessive tool wear.

When using carbide insert drills, it is essential to follow proper drilling techniques to achieve optimal results. This includes using the correct cutting parameters, such as cutting speed and feed rate, as well as maintaining proper chip evacuation to prevent chip buildup and tool breakage. Additionally, using coolant or lubricant during drilling can help improve chip evacuation and extend tool life.

In conclusion, understanding the basics of carbide insert drills is essential for maximizing drilling efficiency and achieving superior results. By selecting the right carbide inserts, maintaining the tool properly, and following proper drilling techniques, you can harness the power of carbide insert drills to tackle even the toughest drilling applications with ease.

- Advantages of Using Carbide Insert Drills for Efficienc

Carbide insert drills have become the ultimate tool for efficient drilling in various industries. With their numerous advantages over traditional drills, they have revolutionized the way drilling is done. In this comprehensive guide, we will delve into the benefits of using carbide insert drills and why they are the preferred choice for many professionals.

One of the main advantages of carbide insert drills is their durability. Carbide is an extremely hard and wear-resistant material, making it ideal for drilling in tough materials such as metal, stainless steel, and hardened steel. Unlike traditional drill bits that wear out quickly, carbide insert drills can last longer and maintain their sharpness for a longer period of time. This means less downtime for tool changes and increased productivity for the user.

Another advantage of using carbide insert drills is their precision. The sharp cutting edges of carbide inserts allow for cleaner and more accurate holes to be drilled, resulting in better quality work. This precision is crucial in industries where accuracy is paramount, such as aerospace and automotive manufacturing.

Additionally, carbide insert drills provide faster drilling speeds compared to traditional drills. The hardness of carbide allows for higher cutting speeds, which can greatly reduce the time needed to complete drilling tasks. This increased efficiency can lead to cost savings for businesses and improved turnaround times on projects.

Furthermore, carbide insert drills are versatile tools that can be used in a wide range of applications. Whether drilling through metal, wood, or composites, carbide insert drills can provide the precision and performance needed for the job. This versatility makes them a valuable tool for professionals across different industries.

In conclusion, carbide insert drills are the ultimate tool for efficient drilling due to their durability, precision, speed, and versatility. By investing in carbide insert drills, professionals can enhance their drilling capabilities and achieve superior results in their work. With the numerous advantages that carbide insert drills offer, it is no wonder they have become the preferred choice for many professionals in the industry.

- How to Choose the Right Carbide Insert Drill for Your Project

Carbide insert drills are an essential tool for any project that involves drilling into tough materials like metal, wood, or concrete. These drills are designed to provide unmatched precision, efficiency, and durability, making them the ultimate tool for any drilling task. However, with so many options available on the market, choosing the right carbide insert drill for your project can be a daunting task. In this comprehensive guide, we will explore everything you need to know about carbide insert drills and how to choose the right one for your specific project.

First and foremost, it is important to understand what sets carbide insert drills apart from traditional drills. Carbide insert drills are made with a high-performance carbide material that is incredibly hard and durable. This allows them to maintain their sharpness and efficiency even when drilling into the toughest materials. Additionally, carbide insert drills feature replaceable inserts that can be easily swapped out when they become worn or dull, extending the life of the drill and saving you time and money on replacements.

When choosing a carbide insert drill for your project, there are a few key factors to consider. The first consideration is the type of material you will be drilling into. Carbide insert drills come in a variety of designs and configurations, each tailored to specific materials and applications. For example, if you will be drilling into metal, you will want to choose a carbide insert drill designed specifically for metal drilling to ensure optimal performance and efficiency.

Another important factor to consider when choosing a carbide insert drill is the size and shape of the drill bit. Different projects require different drill bit sizes and shapes, so it is crucial to choose a carbide insert drill that is compatible with the specific requirements of your project. Additionally, consider the helix angle of the drill bit, as this can affect the efficiency and precision of the drilling process.

In addition to considering the material and size of the drill bit, it is also important to consider the coating of the carbide insert drill. Coatings such as titanium nitride or titanium carbonitride can help to reduce friction, increase wear resistance, and improve chip evacuation, resulting in a smoother and more efficient drilling process.

Finally, when choosing a carbide insert drill for your project, consider the brand and reputation of the manufacturer. While there are many reputable brands that produce high-quality carbide insert drills, it is always a good idea to do your research and read reviews from other customers to ensure you are choosing a reliable and durable product.

In conclusion, carbide insert drills are the ultimate tool for efficient drilling, offering unmatched precision, durability, and performance. By considering factors such as material, drill bit size and shape, coating, and manufacturer reputation, you can choose the right carbide insert drill for your project and achieve optimal results. So, next time you embark on a drilling project, be sure to arm yourself with a high-quality carbide insert drill and watch as it effortlessly powers through even the toughest materials with ease.

- Tips for Proper Maintenance and Care of Carbide Insert Drills

Carbide insert drills are essential tools in the world of drilling, known for their efficiency and effectiveness in various drilling applications. These drills are commonly used in industries such as manufacturing, construction, and metal fabrication. However, like any tool, carbide insert drills require proper maintenance and care to ensure optimal performance and longevity. In this article, we will provide you with some valuable tips for maintaining and caring for your carbide insert drills.

First and foremost, it is important to regularly inspect your carbide insert drills for any signs of wear or damage. This includes checking the cutting edges of the inserts for chips or cracks, as well as inspecting the overall condition of the drill body. If you notice any issues, such as dull or damaged inserts, it is important to replace them immediately to prevent further damage and ensure consistently high-quality drilling results.

In addition to regular inspections, it is also crucial to properly clean and lubricate your carbide insert drills after each use. This helps prevent buildup of debris and contaminants that can affect the performance of the drill. Use a soft brush to remove any chips or residue from the inserts, and apply a high-quality cutting fluid or lubricant to reduce friction and heat during drilling. This not only improves the efficiency of the drill but also extends its lifespan.

Furthermore, it is essential to store your carbide insert drills properly to protect them from damage and ensure their longevity. Store the drills in a dry, cool place away from direct sunlight and moisture. Avoid storing them near other tools or materials that could potentially scratch or damage the inserts. Consider using protective cases or containers to keep the drills organized and safe from harm.

Another important aspect of caring for carbide insert drills is to use them properly according to the manufacturer's recommendations. This includes using the correct cutting speeds and feeds, as well as ensuring proper alignment and clamping of the drill. Improper use can result in premature wear and damage to the inserts, reducing the effectiveness and lifespan of the drill.

In conclusion, carbide insert drills are powerful tools that can greatly enhance drilling efficiency and productivity. By following these tips for proper maintenance and care, you can ensure that your drills perform at their best and last for a long time. Remember to inspect, clean, lubricate, store, and use your carbide insert drills correctly to maximize their potential and achieve the best results in your drilling operations.

- Exploring Advanced Techniques for Maximizing Efficiency with Carbide Insert Drills

Carbide insert drills are a vital tool in the world of metalworking, offering unparalleled efficiency and precision. These versatile tools are designed for drilling holes in various materials, including metal, plastics, and composites. In this guide, we will delve into advanced techniques for maximizing efficiency with carbide insert drills, showcasing why they are the ultimate tool for efficient drilling.

Carbide insert drills are made from a durable and heat-resistant material called carbide, which is known for its hardness and wear resistance. This allows for faster and more efficient drilling compared to traditional high-speed steel drills. The carbide inserts on the drill bit can be easily replaced when they become worn out, saving time and money in the long run.

One of the key techniques for maximizing efficiency with carbide insert drills is to use the correct speed and feed rates. This ensures that the drill bit does not overheat and wear out prematurely. The recommended speed and feed rates depend on the material being drilled and the size of the hole. It is important to consult the manufacturer's guidelines for the specific drill bit being used.

Another advanced technique for maximizing efficiency with carbide insert drills is to use peck drilling. This involves drilling the hole in increments, retracting the drill bit periodically to clear away chips and cool the cutting edge. Peck drilling helps prevent chip buildup, reduces heat generation, and prolongs the life of the drill bit.

In addition to speed, feed rates, and peck drilling, another important factor to consider when using carbide insert drills is the type of coolant or lubricant being used. Coolant helps reduce heat and friction during the drilling process, extending the life of the drill bit and improving overall drilling performance. It is crucial to select the right coolant for the material being drilled and to ensure proper lubrication throughout the drilling operation.

Furthermore, the choice of carbide insert drill geometry can also impact drilling efficiency. Different drill geometries are optimized for specific applications, such as drilling deep holes or achieving high precision. By selecting the right drill geometry for the job, operators can maximize drilling performance and achieve superior results.

In conclusion, carbide insert drills are the ultimate tool for efficient drilling, offering unparalleled precision and durability. By implementing advanced techniques such as optimizing speed and feed rates, using peck drilling, selecting the right coolant, and choosing the appropriate drill geometry, operators can maximize efficiency and productivity in their drilling operations. With the right tools and techniques, carbide insert drills can help take drilling operations to the next level of performance and precision.

Conclusion

In conclusion, carbide insert drills are undoubtedly the ultimate tool for efficient drilling. From their exceptional durability and resistance to high temperatures, to their precision and versatility, these drills have revolutionized the drilling industry. Not only do they save time and effort, but they also ensure accurate and clean cuts in a variety of materials. Whether you're a professional contractor or a DIY enthusiast, investing in carbide insert drills is a decision that will undoubtedly enhance your drilling experience. So, why settle for anything less when you can have the ultimate tool for efficient drilling? Upgrade to carbide insert drills and experience the power and precision that will take your drilling projects to a whole new level.