PCBN Tools: Types And Benefits

Are you looking to learn more about PCBN tools and how they can benefit your machining operations? Look no further! In this article, we will explore the different types of PCBN tools and their numerous benefits. Whether you are new to the world of PCBN tools or are looking to expand your knowledge, this article has something for everyone. Read on to discover how PCBN tools can revolutionize your machining processes.

PCBN Tools: Types and Benefits

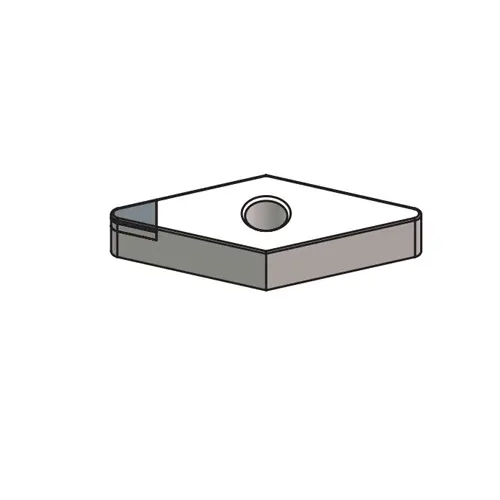

PCBN (polycrystalline cubic boron nitride) tools are a type of cutting tool used in machining processes. These tools are known for their superior hardness, wear resistance, and thermal conductivity, making them ideal for cutting hard materials like hardened steels, cast irons, and superalloys. In this article, we will explore the different types of PCBN tools available and the benefits they offer to manufacturing and machining processes.

Types of PCBN Tools

There are two primary types of PCBN tools: solid and tipped. Solid PCBN tools are made entirely of PCBN material and are typically used for roughing and finishing operations. Tipped PCBN tools, on the other hand, consist of a carbide substrate with a PCBN insert, offering the advantage of cost-effectiveness and the ability to replace the PCBN insert when it wears out.

1. Solid PCBN Tools

Solid PCBN tools are commonly used in applications where high-speed machining and precision are required. These tools are capable of withstanding high cutting temperatures and can maintain their sharpness for extended periods, resulting in improved surface finishes and dimensional accuracy. Solid PCBN tools come in various shapes and sizes, including inserts, end mills, and drills, making them suitable for a wide range of machining operations.

2. Tipped PCBN Tools

Tipped PCBN tools are popular in the manufacturing industry due to their versatility and cost-effectiveness. The carbide substrate provides strength and support to the PCBN insert, allowing for higher cutting speeds and feeds. When the PCBN insert becomes worn or damaged, it can be easily replaced without the need to discard the entire tool, saving time and reducing tooling costs. Tipped PCBN tools are available in different geometries and cutting edge designs to accommodate various machining requirements.

Benefits of PCBN Tools

The use of PCBN tools in manufacturing and machining processes offers several key benefits that contribute to improved productivity, efficiency, and cost savings.

1. Enhanced Tool Life

PCBN tools have a significantly longer tool life compared to traditional cutting tools, reducing the frequency of tool changes and downtime. This extended tool life is attributed to the exceptional hardness and wear resistance of PCBN, allowing for consistent performance and reliable machining operations.

2. Increased Productivity

The superior cutting capabilities of PCBN tools enable higher cutting speeds and feeds, resulting in increased material removal rates and shorter cycle times. This improved productivity leads to higher throughput and reduced lead times in production environments.

3. Improved Surface Finish

The precision and sharpness of PCBN tools contribute to superior surface finishes on machined components. This is particularly advantageous in applications where surface quality is critical, such as in the automotive and aerospace industries.

4. Cost Savings

While the initial investment in PCBN tools may be higher than traditional cutting tools, the long-term cost savings are substantial. The extended tool life, increased productivity, and reduced downtime associated with PCBN tools translate to lower overall machining costs and improved profitability.

5. Versatility

PCBN tools are capable of machining a wide range of materials, including hardened steels, cast irons, and superalloys. This versatility makes PCBN tools a practical choice for manufacturers that work with diverse materials and machining requirements.

In conclusion, PCBN tools offer a variety of advantages that make them a valuable asset in manufacturing and machining operations. Whether it's the exceptional hardness and wear resistance of solid PCBN tools or the cost-effective versatility of tipped PCBN tools, the benefits of using PCBN tools are evident in improved tool life, increased productivity, superior surface finishes, cost savings, and versatility in machining various materials. As technology continues to advance, PCBN tools will undoubtedly play a significant role in shaping the future of precision machining and manufacturing.

Conclusion

In conclusion, PCBN tools offer a wide range of benefits for machining operations, including increased tool life, improved surface finish, and higher productivity. With their various types such as inserts, solid PCBN, and PCBN tipped tools, manufacturers have a versatile selection to choose from to suit their specific machining needs. The use of PCBN tools also leads to cost savings and overall efficiency, making them a valuable investment for companies. As technology continues to advance, the advantages of PCBN tools will only become more apparent, making them an essential tool for modern machining processes. Whether it's for turning, milling, or boring, PCBN tools are a game changer in the machining industry, and their benefits cannot be overstated.