Mastering The Art Of Precision: A Guide To Using A Thread Cutting Tool

Welcome to our comprehensive guide on mastering the art of precision with thread cutting tools. In this article, we will walk you through all the essential steps and tips you need to know to effectively use a thread cutting tool. Whether you are a beginner or an experienced craftsman, this guide will help you elevate your skills and achieve precise and professional results in your projects. Let's dive in and explore the world of thread cutting tools together!

- Understanding the Importance of Precision in Thread Cutting

Thread cutting tools are essential for creating precise and accurate threads in various materials, making them a crucial component in many industries such as machining, automotive, plumbing, and woodworking. Understanding the importance of precision in thread cutting is crucial for achieving high-quality results and ensuring that the threads fit together seamlessly. This guide will explore the key concepts and techniques involved in using a thread cutting tool effectively.

One of the most important aspects of using a thread cutting tool is selecting the right tool for the job. Thread cutting tools come in a variety of sizes and types, each designed for specific thread sizes and materials. It is essential to choose a thread cutting tool that matches the thread size and material you are working with to ensure accurate and clean threads. Using the wrong tool can result in poorly formed threads, uneven thread depths, and thread misalignments, leading to problems with assembly and performance.

Once you have selected the right thread cutting tool, the next step is to prepare the workpiece for threading. This involves accurately marking the starting point for the thread, ensuring that the workpiece is securely held in place, and aligning the tool properly with the workpiece. It is crucial to take the time to set up the workpiece correctly to ensure that the threads are cut accurately and to prevent any damage to the workpiece or the tool.

Another essential aspect of precision in thread cutting is maintaining proper cutting speed and pressure. Cutting too quickly can result in ragged or uneven threads, while cutting too slowly can cause the tool to bind or break. It is important to find the right balance between speed and pressure to achieve clean and precise threads. Additionally, using lubrication while cutting threads can help reduce friction and heat, preventing tool wear and producing smoother threads.

In addition to speed and pressure, the cutting angle of the tool is also crucial for achieving precise threads. The cutting angle determines the shape and depth of the threads, so it is essential to set the tool at the correct angle for the desired thread profile. Adjusting the cutting angle may be necessary depending on the material being threaded, as different materials require different cutting angles for optimal results.

Overall, mastering the art of precision in thread cutting requires attention to detail, patience, and practice. By selecting the right tool, preparing the workpiece correctly, maintaining the proper cutting speed and pressure, and adjusting the cutting angle as needed, you can create clean, accurate threads that fit together perfectly. Understanding the importance of precision in thread cutting is key to producing high-quality threaded components and achieving success in various industries.

- Choosing the Right Thread Cutting Tool for Your Project

In the world of precision engineering and machining, choosing the right thread cutting tool is essential to the success of any project. Whether you are working on a small DIY project at home or a large-scale industrial manufacturing process, the selection of the right tool can make all the difference in the final outcome.

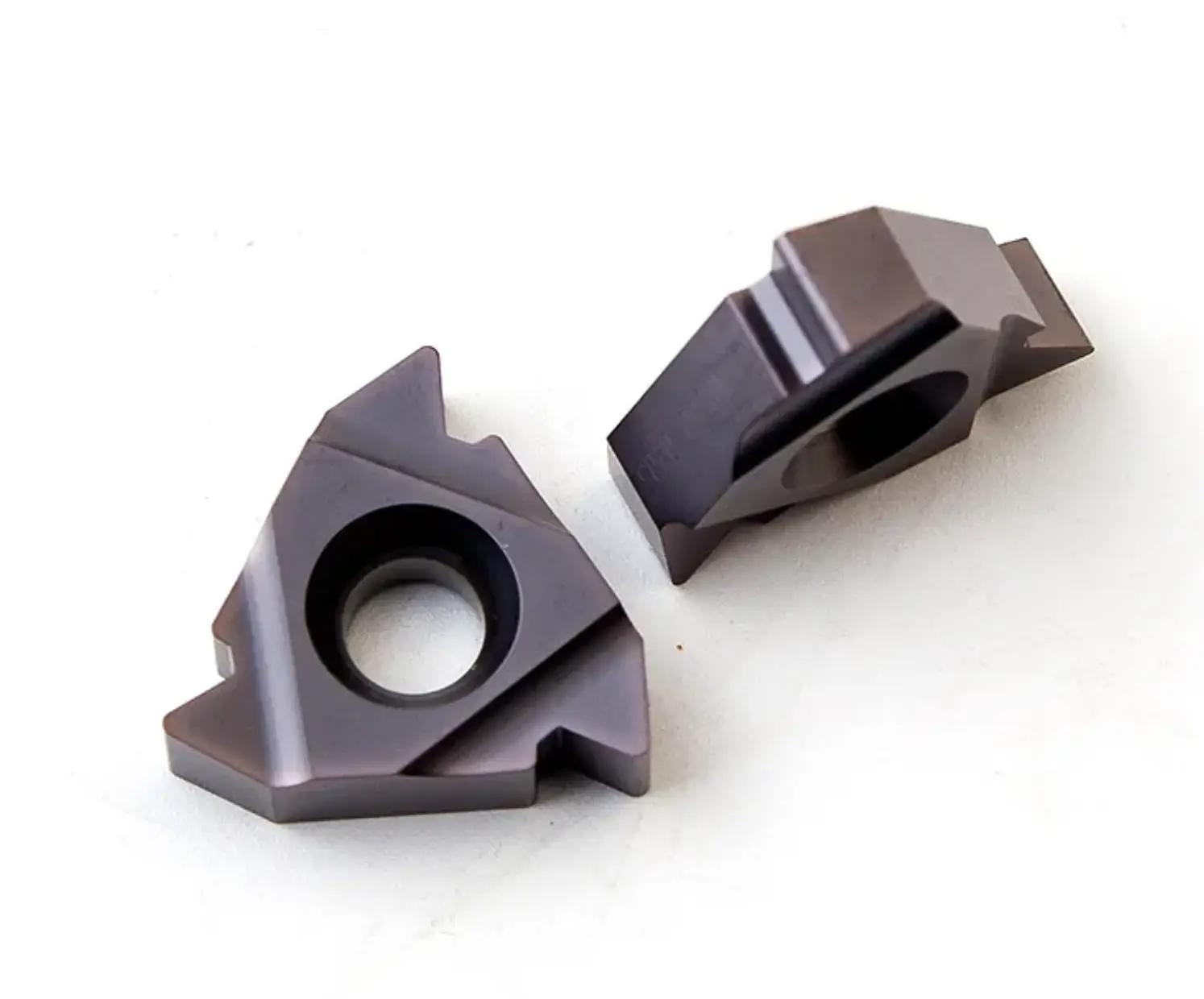

Thread cutting tools come in a variety of shapes, sizes, and materials, each designed for a specific type of project and material. From taps and dies to thread mills and thread forming tools, there is a wide range of options available to suit your needs. Understanding the differences between these tools and knowing how to choose the right one for your project is crucial to achieving accurate and efficient results.

When selecting a thread cutting tool, there are several factors to consider. The first is the type of material you will be working with. Different materials require different types of thread cutting tools to achieve the best results. For example, softer materials such as aluminum may require a different type of tool than harder materials like steel. It is important to match the tool to the material to ensure clean and accurate threads.

In addition to material, the size of the thread and the pitch of the thread must also be taken into account when selecting a thread cutting tool. Different tools are designed for different thread sizes and pitches, so it is important to choose the right tool for the job. Using the wrong tool can result in damaged threads or poor quality finishes, so it is crucial to pay attention to these details.

Another factor to consider when choosing a thread cutting tool is the type of thread you need to create. There are several types of threads, including straight threads, tapered threads, and pipe threads, each requiring a different type of tool to produce. It is important to select a tool that is designed for the specific type of thread you are working with to ensure precision and accuracy.

When it comes to actually using a thread cutting tool, there are several tips and techniques to keep in mind. Always make sure to use the correct cutting speed and feed rate for the material you are working with to prevent tool breakage and achieve clean, accurate threads. Lubrication is also key to successful thread cutting, as it helps to reduce friction and heat build-up, resulting in smoother cutting and longer tool life.

In conclusion, choosing the right thread cutting tool for your project is essential to achieving precise and high-quality results. By considering factors such as material, thread size and pitch, and thread type, and using the proper techniques for cutting threads, you can master the art of precision machining and ensure the success of your project.

- Mastering the Techniques of Using a Thread Cutting Tool

Mastering the art of precision is essential for any craftsman or DIY enthusiast looking to create high-quality products. One of the key tools for achieving precision in metalworking is the thread cutting tool. In this comprehensive guide, we will delve into the techniques and strategies necessary to effectively use a thread cutting tool and achieve precise results.

First and foremost, it is important to understand the different types of thread cutting tools available. The most common types include die heads, taps, and dies. Die heads are typically used for cutting external threads, while taps are used for cutting internal threads. Dies, on the other hand, are used for cutting external threads on cylindrical objects. Each type of tool has its own specific purpose and should be chosen based on the requirements of the project at hand.

When using a thread cutting tool, it is crucial to start with the correct size and type of thread. Using the wrong size or type of thread can result in a poor fit and potentially damage the workpiece. Before starting the cutting process, it is advisable to measure the diameter and pitch of the thread to ensure that the correct tool is selected.

Next, it is important to properly secure the workpiece before using the thread cutting tool. This can be done using clamps or a vise to prevent the workpiece from moving during the cutting process. Additionally, it is important to lubricate the cutting tool and workpiece to reduce friction and prevent overheating, which can cause damage to the threads.

When using a thread cutting tool, it is best to start by creating a pilot hole with a drill bit of the appropriate size. This will guide the thread cutting tool and ensure that the threads are cut straight and true. It is important to apply steady pressure and turn the tool in a clockwise direction to cut the threads smoothly.

As you continue to cut the threads, it is important to periodically back off the tool to break the chips that are being formed. This will prevent the chips from getting stuck in the threads and causing damage. Additionally, it is important to periodically clean and lubricate the cutting tool to ensure optimal cutting performance.

In conclusion, mastering the techniques of using a thread cutting tool requires practice, patience, and attention to detail. By following the tips and strategies outlined in this guide, you can achieve precise and accurate results in your metalworking projects. Remember to always choose the correct size and type of thread cutting tool, secure the workpiece properly, and lubricate the cutting tool and workpiece to prevent damage. With practice and dedication, you can become a master of using a thread cutting tool and create high-quality products with precision and accuracy.

- Tips and Tricks for Achieving Perfect Thread Cuts

In today’s fast-paced world, it is easy to overlook the importance of precision in every task we undertake. When it comes to working with materials like metal or wood, achieving perfect thread cuts is essential for ensuring a high-quality end product. This is where a thread cutting tool comes into play, offering a versatile and efficient solution for creating clean and accurate threads.

A thread cutting tool is a specialized tool designed to cut threads on various materials, including metal, plastic, and wood. It consists of a cutting blade or die that is used to remove material and create the grooves necessary for the thread to form. Whether you are a seasoned professional or a DIY enthusiast, mastering the art of using a thread cutting tool can greatly improve the quality of your work.

One of the key tips for achieving perfect thread cuts is to ensure that the material you are working with is securely clamped in place. This will prevent any movement or vibration that can lead to uneven cuts or damaged threads. Additionally, using the proper lubricant can greatly improve the cutting process by reducing friction and heat buildup. This results in smoother cuts and extends the life of your cutting tool.

When using a thread cutting tool, it is important to start with the correct size and pitch of the thread you are trying to create. This will ensure a tight and secure fit when the threaded piece is assembled. It is also crucial to maintain a steady hand and apply consistent pressure while cutting the threads to avoid any errors or irregularities.

Another valuable tip for achieving perfect thread cuts is to use the proper technique for your specific material. Different materials require different cutting speeds, pressures, and lubricants to achieve the best results. For example, cutting threads in metal may require a slower cutting speed and a heavier lubricant to prevent the tool from overheating, while cutting threads in wood may require a faster speed and a lighter lubricant for smoother cuts.

In addition to these tips, there are several tricks that can help you master the art of using a thread cutting tool. For example, marking the starting point of your cut with a center punch can help guide the cutting tool and ensure a straight and accurate thread. Additionally, regularly inspecting and sharpening the cutting blade or die can help maintain the tool’s effectiveness and prevent premature wear.

Overall, mastering the art of precision when using a thread cutting tool requires a combination of proper technique, attention to detail, and patience. By following these tips and tricks, you can elevate the quality of your work and achieve perfect thread cuts every time. So, the next time you embark on a project that requires threads, be sure to utilize the invaluable tool that is the thread cutting tool.

- Maintaining and Caring for Your Thread Cutting Tool to Ensure Longevity

The key to mastering the art of precision in threading lies in understanding how to properly use and care for your thread cutting tool. In this guide, we will explore the importance of maintaining your tool to ensure its longevity and effectiveness.

A thread cutting tool is a vital instrument in any workshop or manufacturing setting, used to create threads on a variety of materials such as metal, plastic, or wood. Whether you are a seasoned professional or a novice DIY enthusiast, knowing how to effectively use and care for your thread cutting tool is essential for achieving accurate and high-quality results.

To begin, it is crucial to select the appropriate thread cutting tool for the job at hand. There are various types of thread cutting tools available, including taps, dies, and thread mills, each designed for specific applications. It is important to choose the right tool based on the material being threaded, the desired thread size and pitch, and the machining process being used.

Once you have selected the appropriate thread cutting tool, it is important to ensure that it is properly maintained to maximize its lifespan and performance. Regular cleaning and lubrication of the tool are essential to prevent corrosion and maintain smooth operation. After each use, be sure to remove any debris or metal shavings from the tool and apply a thin coat of oil to prevent rust.

In addition to regular maintenance, it is also important to store your thread cutting tool properly when not in use. Storing the tool in a dry and temperature-controlled environment will help prevent rust and corrosion, ensuring that it remains in optimal condition for future use. Avoid storing the tool in damp or humid conditions, as this can lead to premature wear and damage.

Furthermore, it is important to use the correct cutting speed and feed rate when using a thread cutting tool. Operating the tool at the appropriate speed and feed rate will help prevent overheating and premature wear, ensuring that the tool operates efficiently and produces precise threads. Refer to the manufacturer's guidelines for recommended speeds and feeds for optimal performance.

In conclusion, mastering the art of precision in threading requires not only skill and expertise but also proper maintenance and care of your thread cutting tool. By selecting the right tool, maintaining it regularly, storing it properly, and using it at the correct speed and feed rate, you can ensure that your thread cutting tool remains in top condition for years to come. By following these simple guidelines, you can achieve accurate and high-quality threads with ease and confidence.

Conclusion

In conclusion, mastering the art of precision when using a thread cutting tool is essential for achieving optimal results in machining processes. This guide has provided valuable tips and techniques to help you enhance your skills in using these tools effectively. By following the advice outlined in this article, you can elevate your craftsmanship and achieve greater precision in your work. Remember, practice makes perfect, so keep honing your skills and experimenting with different techniques to become a master in the art of precision. Happy threading!