Thread Cutting Tool: Types And Applications

Welcome to our comprehensive guide on thread cutting tools! If you're looking to enhance your knowledge of different types of thread cutting tools and their applications, you've come to the right place. In this article, we will delve into the various types of thread cutting tools, their functionalities, and how they are utilized in different industries. Whether you're a seasoned professional or a beginner in the field, this article will provide valuable insights to help you understand the importance and practical applications of these essential tools. So, grab a seat, and let's explore the world of thread cutting tools together!

Thread Cutting Tool: Types and Applications

When it comes to cutting threads in various materials, having the right tools for the job is essential. Thread cutting tools come in a variety of types and are used in a wide range of applications. In this article, we will explore the different types of thread cutting tools available and their respective applications.

Types of Thread Cutting Tools

1. Taps

Taps are one of the most commonly used thread cutting tools. They are used to cut internal threads in materials such as metal and plastic. There are several types of taps, including hand taps, spiral point taps, and spiral flute taps. Hand taps are used for manual threading, while spiral point and spiral flute taps are designed for machine threading. Taps come in various sizes and thread pitches to accommodate different applications.

2. Dies

Dies are the counterpart to taps and are used to cut external threads on materials such as metal and plastic. Like taps, there are different types of dies, including round dies, hexagonal dies, and adjustable dies. Round dies are used for manual threading, while hexagonal and adjustable dies are designed for machine threading. Dies also come in a range of sizes and thread pitches to suit different applications.

3. Thread Mills

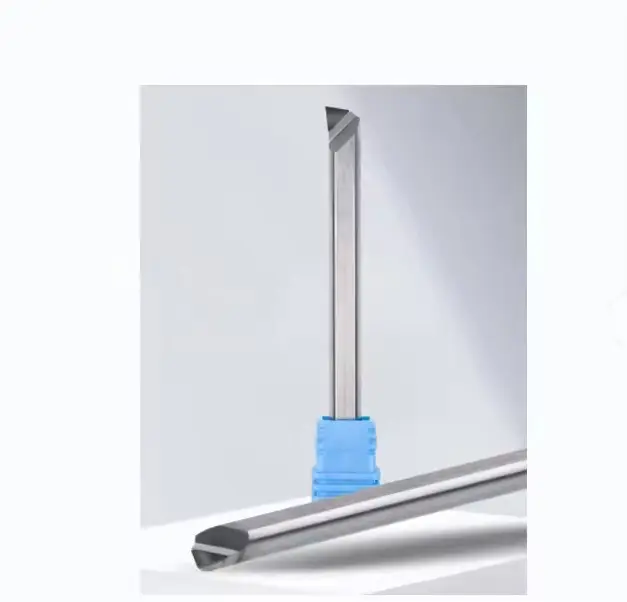

Thread mills are cutting tools that are used to create threads in materials using a milling machine. They are typically used for machining complex or high-precision threads in materials such as metal, plastic, and wood. Thread mills come in various designs, including solid carbide thread mills, helical flute thread mills, and single plane thread mills. They are ideal for applications that require precise and high-quality threading.

4. Thread Chasers

Thread chasers are specialized thread cutting tools that are used to repair or re-cut existing threads. They are commonly used in automotive and aerospace applications where damaged threads need to be restored without removing the workpiece. Thread chasers come in different styles, including single-point thread chasers and multi-point thread chasers. They are a versatile tool for maintaining and repairing threads in various materials.

5. Thread Cutting Inserts

Thread cutting inserts are cutting tools that are used in conjunction with a threading tool holder to create internal or external threads in materials. They are commonly used in CNC machining and turning operations. Thread cutting inserts come in different shapes and materials, including carbide, ceramic, and high-speed steel. They are designed to provide high cutting speeds and long tool life, making them suitable for high-volume production environments.

Applications of Thread Cutting Tools

1. Metalworking

Thread cutting tools are widely used in metalworking applications, including machining, fabrication, and assembly. They are essential for creating threaded holes, bolts, and other fasteners in metal components. Taps, dies, thread mills, and thread cutting inserts are all commonly used in metalworking operations to produce high-quality threads with precise dimensions.

2. Woodworking

In woodworking applications, thread cutting tools are used to create threaded holes and fasteners in wooden components. Thread mills and thread cutting inserts are often used for machining wooden materials, such as furniture, cabinetry, and architectural millwork. Thread chasers are also useful for repairing damaged threads in wooden pieces without compromising their structural integrity.

3. Plastic Fabrication

Thread cutting tools are also utilized in plastic fabrication applications, where they are used to create threaded holes and fasteners in plastic components. Taps and dies, as well as thread cutting inserts, are commonly used in plastic fabrication operations to produce durable and secure threads in various types of plastic materials.

4. Automotive and Aerospace

In the automotive and aerospace industries, thread cutting tools play a crucial role in the manufacturing and maintenance of vehicles and aircraft. Thread chasers are frequently used for repairing damaged threads in engine components and aerospace structures. Thread cutting inserts are also used in CNC machining to produce high-precision threads in critical components for automotive and aerospace applications.

5. General Maintenance and Repair

Thread cutting tools are indispensable for general maintenance and repair tasks in various industries. From fixing damaged threads in machinery to creating custom fasteners for equipment, taps, dies, and thread chasers are essential tools for any maintenance or repair shop. They enable technicians to quickly and effectively address threading issues without having to replace entire components.

Thread cutting tools are essential for a wide range of applications in various industries, from metalworking and woodworking to plastic fabrication and automotive/aerospace manufacturing. With the right types of thread cutting tools and the proper techniques, it is possible to create strong and precise threads in a variety of materials. Understanding the different types of thread cutting tools and their applications is essential for selecting the right tool for the job and achieving the desired threading results. Whether it's creating new threads, repairing damaged threads, or producing high-precision threads, thread cutting tools are a valuable asset for any manufacturing or maintenance operation.

Conclusion

In conclusion, the world of thread cutting tools is vast and diverse, with a wide range of types and applications to suit different needs. Whether you are a professional machinist or a DIY enthusiast, understanding the various types of thread cutting tools and their applications can be incredibly beneficial. From taps and dies to thread mills and thread chasers, these tools play a crucial role in creating threaded holes and bolts in a variety of materials. By choosing the right tool for the job and understanding how to use it effectively, you can ensure precise and efficient thread cutting operations. So, whether you're working on a metal fabrication project or simply need to repair an old piece of machinery, having a good understanding of thread cutting tools can help you achieve the best results.