Carbide Insert Drill: Applications In High-Speed Drilling Operations

Are you looking to maximize the efficiency and performance of your high-speed drilling operations? Look no further than the carbide insert drill. In this article, we will explore the various applications of carbide insert drills and how they can revolutionize your drilling processes. Whether you are in the manufacturing, construction, or automotive industry, understanding the benefits of carbide insert drills is essential for enhancing productivity and achieving optimal results. Join us as we delve into the world of high-speed drilling with carbide insert drills and discover how they can take your operations to the next level.

Carbide Insert Drill: Applications in High-Speed Drilling Operations

When it comes to high-speed drilling operations, the choice of drill can make all the difference in the efficiency and effectiveness of the process. One of the most popular options for high-speed drilling is the carbide insert drill, known for its durability and precision. In this article, we will explore the various applications of the carbide insert drill in high-speed drilling operations and the benefits it offers.

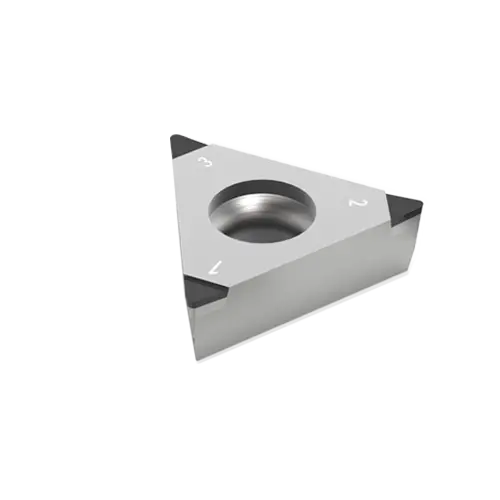

Understanding the Carbide Insert Drill

Before we delve into the applications of the carbide insert drill, it is important to understand what sets it apart from other types of drills. The carbide insert drill is equipped with cutting edges made from carbide inserts, which are known for their exceptional hardness and heat resistance. This allows the drill to withstand the high temperatures and forces generated during high-speed drilling operations, making it an ideal choice for such applications.

Applications in Aerospace Manufacturing

One of the key industries that greatly benefit from the use of carbide insert drills in high-speed drilling operations is aerospace manufacturing. The drilling of precision holes in aerospace components requires high-speed and high-precision tools, and the carbide insert drill delivers on both fronts. Whether it is drilling holes in titanium, aluminum, or composite materials, the carbide insert drill ensures clean and accurate results, making it a crucial tool in aerospace manufacturing.

High-Speed Drilling in Automotive Production

In the automotive industry, high-speed drilling operations are essential for the fabrication of various components such as engine blocks, transmission housings, and chassis components. The use of carbide insert drills in these operations allows for improved productivity and cost-efficiency. The durability of the carbide inserts ensures extended tool life, reducing the frequency of tool changes and minimizing downtime in the production process.

Oil and Gas Exploration

The drilling of oil and gas wells demands high-speed drilling operations that can withstand the challenging conditions encountered in the exploration process. Carbide insert drills are well-suited for this application, as they can effectively drill through hard rock formations and abrasive materials commonly found in oil and gas reservoirs. The heat resistance of the carbide inserts allows for sustained performance even in high-temperature environments, making them an indispensable tool in oil and gas exploration.

Benefits of Using Carbide Insert Drills

There are several key benefits to using carbide insert drills in high-speed drilling operations. Firstly, their exceptional hardness and heat resistance ensure extended tool life, reducing the need for frequent replacements and maintenance. This translates to cost savings and improved productivity in the long run. Additionally, the precision and accuracy of carbide insert drills result in consistent and high-quality drilled holes, meeting the stringent requirements of various industries.

In conclusion, the carbide insert drill is a versatile and reliable tool for high-speed drilling operations in a variety of industries. Its applications in aerospace manufacturing, automotive production, and oil and gas exploration highlight its ability to deliver precise and efficient results in challenging drilling environments. With its durability, heat resistance, and cost-efficiency, the carbide insert drill continues to be a popular choice for high-speed drilling operations. Its efficacy in these applications makes it a valuable tool for manufacturers and drilling professionals alike. As a leading manufacturer of carbide insert drills, VeryCarbon is committed to providing high-quality tools that meet the demands of high-speed drilling operations across industries. With our expertise and innovation, we continue to deliver cutting-edge solutions for the most demanding drilling challenges.

Conclusion

In conclusion, carbide insert drills are an essential tool in high-speed drilling operations, offering superior performance and durability compared to traditional high-speed steel drills. Their ability to withstand high temperatures and maintain sharp cutting edges makes them ideal for drilling operations in tough materials such as stainless steel, titanium, and other alloys. With their wide range of applications and impressive capabilities, it's no wonder that carbide insert drills have become a go-to choice for professionals in the manufacturing and metalworking industries. As technology continues to advance, we can expect to see even more innovative applications for carbide insert drills, further solidifying their place as a staple tool in high-speed drilling operations.