Roughing Mill Cutter: Features And Applications

Welcome to our in-depth exploration of roughing mill cutters and their wide-ranging features and applications. Whether you are a seasoned professional in the manufacturing industry or just starting to delve into the world of machining, this article will provide valuable insights into the functionality and versatility of roughing mill cutters. From their unique design features to their diverse applications in various industries, this comprehensive guide will equip you with the knowledge you need to understand and leverage the power of roughing mill cutters. So, grab a cup of coffee, sit back, and let's dive into the world of roughing mill cutters together!

Roughing Mill Cutter: Features and Applications

to Roughing Mill Cutter

Roughing mill cutters are essential tools in the metalworking industry, specifically used for removing large amounts of material during the roughing process. These cutters are designed to withstand heavy loads and high speeds, making them suitable for demanding machining operations. In this article, we will take a closer look at the features and applications of roughing mill cutters, as well as the benefits they offer to manufacturers.

Features of Roughing Mill Cutter

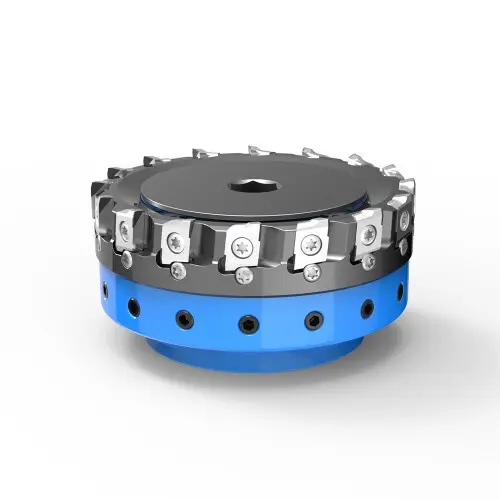

Roughing mill cutters are typically made from high-speed steel (HSS) or carbide, offering excellent wear resistance and heat resistance. They are available in various designs, including solid carbide end mills, indexable insert cutters, and shell mills, each with its unique features and advantages. Many roughing mill cutters feature multiple flutes, which help to increase material removal rates and improve chip evacuation. Additionally, some cutters are coated with specialized materials to further enhance their performance and longevity.

One of the key features of roughing mill cutters is their ability to withstand heavy cutting forces and vibrations. This is achieved through their robust design, which includes reinforced shanks and flutes, as well as optimized geometries to reduce chatter and achieve higher stability during the cutting process. Furthermore, some roughing mill cutters are equipped with coolant channels to facilitate better chip evacuation and cooling, especially when working with tough materials or high-speed machining applications.

Applications of Roughing Mill Cutter

Roughing mill cutters are widely used in various machining operations, including face milling, contour milling, slotting, and pocketing. They are particularly well-suited for roughing operations in the aerospace, automotive, and die and mold industries, where high material removal rates are essential for productivity and efficiency. With their ability to withstand heavy loads and high speeds, roughing mill cutters are also commonly used in the production of large components, such as turbine blades, engine blocks, and die-cast molds.

Moreover, roughing mill cutters are instrumental in the machining of difficult-to-cut materials, such as stainless steel, titanium, and nickel-based alloys. Their robust design and advanced coatings enable them to tackle the challenges posed by these materials, delivering superior performance and longer tool life. Additionally, roughing mill cutters are utilized in high-performance machining centers, where their ability to handle aggressive cutting parameters and maintain stability is crucial for achieving optimal results.

Benefits of Roughing Mill Cutter

The use of roughing mill cutters offers several benefits to manufacturers, including increased productivity, reduced machining time, and improved surface finish. By removing large amounts of material in a single pass, these cutters enable faster cycle times and higher throughput, ultimately resulting in cost savings and improved workflow efficiency. Moreover, their enhanced chip evacuation and cooling capabilities help to prevent tool wear and prolong tool life, reducing the frequency of tool changes and minimizing downtime.

Furthermore, roughing mill cutters contribute to the overall quality of machined components by generating smoother surface finishes and more accurate dimensions. Their advanced geometries and coatings enable them to produce precise and consistent results, while their high-performance capabilities allow manufacturers to achieve better tolerances and part accuracies. Overall, the use of roughing mill cutters enhances the machining process, leading to improved part quality and customer satisfaction.

Roughing mill cutters are indispensable tools for manufacturers seeking to optimize their roughing operations and achieve higher productivity and efficiency. With their robust features, diverse applications, and tangible benefits, these cutters play a vital role in the metalworking industry, contributing to the production of high-quality components and the success of machining operations. As technology continues to advance, the development of new materials and coatings will further enhance the performance and versatility of roughing mill cutters, ensuring their continued relevance and value in the field of metal cutting.

Conclusion

In conclusion, the roughing mill cutter is an essential tool for a variety of applications in the manufacturing industry. Its unique features, such as high-speed performance, durable construction, and efficient chip removal, make it a valuable asset for machining processes. Whether it's used for roughing out large metal pieces or creating rough surfaces on workpieces, this versatile tool provides precision and reliability. With its ability to handle heavy-duty cutting tasks, the roughing mill cutter is a must-have for any workshop or manufacturing facility. Its applications are widespread, ranging from automotive manufacturing to aerospace engineering, making it a crucial component in the production of various goods. Therefore, investing in a high-quality roughing mill cutter is a decision that can greatly improve the efficiency and productivity of machining operations.