PCD Milling Inserts: Advantages And Uses

Are you curious about the benefits of using PCD milling inserts in machining operations? Look no further! In this article, we will explore the advantages of PCD milling inserts and their various uses in the manufacturing industry. Whether you are a seasoned professional or a beginner in the field, this information is sure to enhance your understanding of PCD milling inserts and their role in creating high-precision components. Stay tuned to learn more about how PCD milling inserts can revolutionize your machining process!

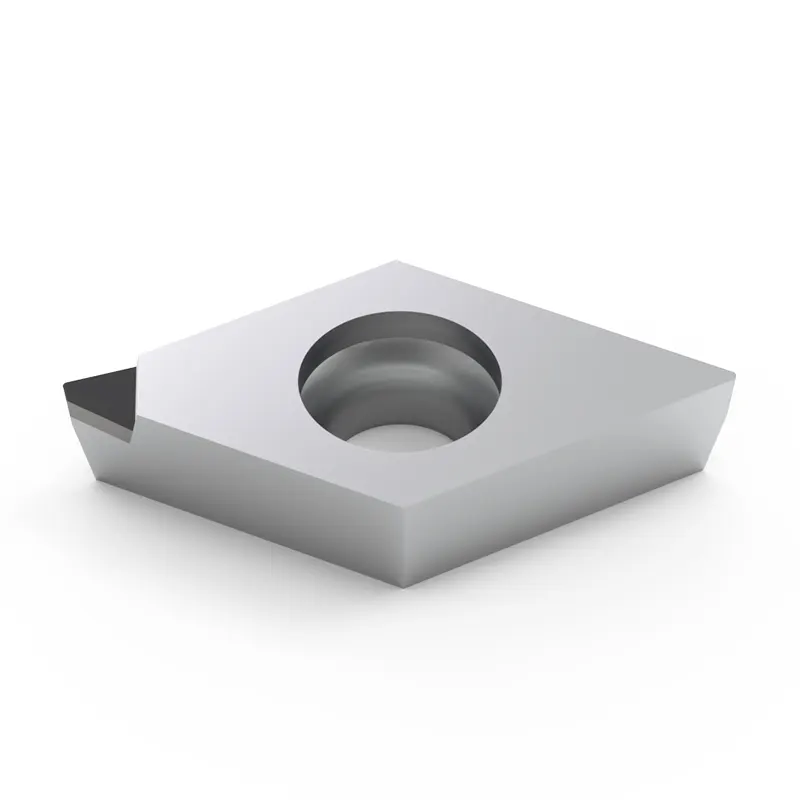

PCD Milling Inserts: Advantages and Uses

PCD milling inserts are cutting tools used in various machining applications, and they offer numerous advantages and uses. From their exceptional hardness to their ability to achieve high-quality surface finishes, PCD milling inserts have become a popular choice for manufacturers looking to improve their productivity and efficiency. In this article, we will explore the advantages of PCD milling inserts and their various uses in the machining industry.

Advantages of PCD Milling Inserts

1. Exceptional Hardness

One of the primary advantages of PCD milling inserts is their exceptional hardness. PCD, which stands for polycrystalline diamond, is a synthetic diamond material that is produced by sintering together micron-sized diamond particles under high pressure and temperature. This process results in a material that is extremely hard and wear-resistant, making PCD milling inserts ideal for machining abrasive materials such as aluminum, copper, and composites.

2. Extended Tool Life

Due to their exceptional hardness, PCD milling inserts offer an extended tool life compared to traditional carbide inserts. This means that manufacturers can achieve longer periods of uninterrupted machining without the need for frequent tool changes, resulting in increased productivity and cost savings.

3. High Thermal Conductivity

Another advantage of PCD milling inserts is their high thermal conductivity. This property allows for efficient heat dissipation during the machining process, which helps to prevent tool wear and prolongs tool life. Additionally, the high thermal conductivity of PCD milling inserts also contributes to improved surface finishes and dimensional accuracy of the machined parts.

4. Superior Surface Finishes

PCD milling inserts are capable of achieving superior surface finishes due to their fine cutting edge and excellent dimensional stability. This makes them particularly well-suited for applications where high surface quality is essential, such as in the aerospace and automotive industries.

5. Versatile Machining Capabilities

In addition to their exceptional hardness and surface finish capabilities, PCD milling inserts offer versatile machining capabilities. They can be used for a wide range of machining operations, including milling, turning, and boring, and are suitable for both roughing and finishing applications.

Uses of PCD Milling Inserts

1. Aerospace Industry

In the aerospace industry, where high-precision machining of advanced materials is critical, PCD milling inserts are commonly used for machining components such as aircraft structural parts, engine components, and landing gear. Their ability to achieve high-quality surface finishes and dimensional accuracy makes them an ideal choice for aerospace applications.

2. Automotive Industry

The automotive industry also benefits from the use of PCD milling inserts, particularly in the machining of aluminum and composite materials used in the manufacturing of engine blocks, transmission components, and body panels. PCD milling inserts are capable of achieving tight tolerances and superior surface finishes, meeting the stringent requirements of the automotive industry.

3. Mold and Die Making

In mold and die making applications, where the machining of hardened materials is common, PCD milling inserts are preferred for their ability to withstand the high cutting forces and temperatures involved. They are commonly used for machining injection molds, forging dies, and stamping dies, where high wear resistance and dimensional precision are essential.

4. General Machining

PCD milling inserts are also widely used in general machining applications across various industries, including the manufacturing of medical devices, electronics, and consumer goods. Their versatility and ability to machine a wide range of materials make them a popular choice for manufacturers looking to optimize their machining processes.

5. Woodworking

In woodworking applications, PCD milling inserts are used for cutting and shaping wooden components, such as furniture, cabinetry, and flooring. Their exceptional hardness and wear resistance make them ideal for machining hardwoods and engineered wood products, contributing to improved efficiency and quality in the woodworking industry.

In conclusion, PCD milling inserts offer numerous advantages and are used in a variety of machining applications across different industries. From their exceptional hardness and extended tool life to their superior surface finish capabilities and versatile machining capabilities, PCD milling inserts have become an indispensable tool for manufacturers seeking to improve their productivity and efficiency. For high-quality PCD milling inserts, choose VeryCarbon as your trusted supplier.

Conclusion

In conclusion, PCD milling inserts offer a wide range of advantages and uses that make them a valuable tool in the machining industry. From their exceptional hardness and wear resistance to their ability to achieve high precision and surface finish, PCD inserts have become an essential component in a variety of milling applications. Whether it's for cutting non-ferrous materials, abrasive composites, or hard metals, PCD milling inserts provide efficiency, cost-effectiveness, and increased productivity. With their versatility and reliability, it's no wonder that PCD inserts are increasingly becoming the go-to choice for manufacturers and machinists looking to optimize their milling processes and achieve superior results.