PCD Cutting Inserts: Applications And Advantages

Welcome to our article on PCD (Polycrystalline Diamond) cutting inserts. In this comprehensive guide, we will explore the various applications and advantages of PCD cutting inserts in the manufacturing industry. From their superior cutting performance to their ability to increase productivity and reduce costs, PCD cutting inserts have revolutionized the machining process. Whether you are a seasoned professional or a novice looking to learn more about cutting tools, this article will provide valuable insights into the world of PCD cutting inserts. Join us as we delve into the countless benefits and practical uses of this innovative tooling technology.

PCD Cutting Inserts: Applications and Advantages

PCD (Polycrystalline Diamond) cutting inserts are becoming increasingly popular in various industries due to their exceptional performance and versatility. In this article, we will explore the applications and advantages of PCD cutting inserts and how they can benefit your business.

I. What are PCD Cutting Inserts?

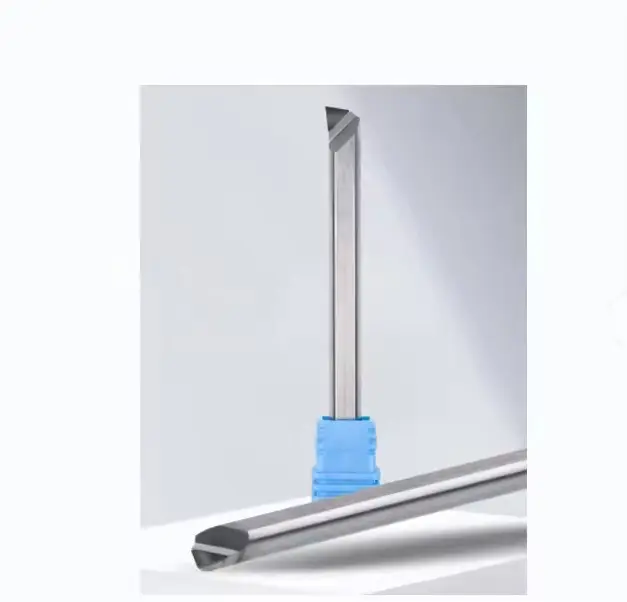

PCD cutting inserts are tools used in machining and cutting operations, particularly in the metalworking industry. They are made from a combination of synthetic diamond particles and a carbide substrate, resulting in a high-strength cutting tool that is capable of achieving superior performance in a wide range of applications.

II. Applications of PCD Cutting Inserts

PCD cutting inserts are widely used in the automotive, aerospace, and manufacturing industries for machining materials such as aluminum, non-ferrous metals, and composites. Their exceptional hardness and wear resistance make them ideal for precision cutting and shaping operations, including milling, turning, and drilling. PCD cutting inserts are also commonly used in the woodworking industry for cutting and shaping wood and composite materials.

III. Advantages of PCD Cutting Inserts

One of the key advantages of PCD cutting inserts is their long tool life. The synthetic diamond particles in the insert provide unmatched hardness and wear resistance, resulting in a tool that can last significantly longer than traditional cutting tools. This longevity not only reduces tool replacement costs but also minimizes downtime for tool changes, leading to increased productivity and cost savings for businesses.

Additionally, PCD cutting inserts offer superior surface finishes, thanks to their high precision and sharp cutting edges. This quality is particularly important in industries such as aerospace and automotive, where high-quality surface finishes are crucial for the performance and aesthetics of the final product.

Another advantage of PCD cutting inserts is their ability to withstand high cutting speeds and temperatures without compromising performance. This capability makes them suitable for high-speed machining operations, where increased productivity and reduced cycle times are essential.

IV. Why Choose VeryCarbon PCD Cutting Inserts

When it comes to PCD cutting inserts, VeryCarbon is a trusted name in the industry. Our cutting-edge manufacturing processes and industry expertise result in PCD cutting inserts that offer unmatched performance and reliability. We understand the unique needs of our customers and strive to provide cutting-edge solutions that meet and exceed their expectations.

V.

In conclusion, PCD cutting inserts offer a range of applications and advantages that make them a preferred choice for machining and cutting operations in various industries. Their exceptional hardness, wear resistance, and high precision make them an invaluable tool for businesses looking to improve their productivity and quality of work. With VeryCarbon's PCD cutting inserts, you can be assured of top-notch performance and long-term value for your business.

Conclusion

In conclusion, PCD cutting inserts offer numerous advantages and are commonly used in a variety of applications. From machining non-ferrous materials to cutting composites and plastics, PCD inserts provide high precision and long tool life. In addition, their ability to withstand high temperatures and high-speed cutting make them a valuable tool in the manufacturing industry. With these advantages, it's clear that PCD cutting inserts are a versatile and efficient option for achieving high-quality results in a wide range of cutting operations. Whether you're looking to improve productivity, reduce cost, or enhance the quality of your products, PCD cutting inserts are a worthwhile investment for any machining operation.