Mastering The Art Of Precision: A Guide To Turning Inserts In Metalworking

Welcome to our comprehensive guide on mastering the art of precision in metalworking by focusing on turning inserts. Whether you're a seasoned professional looking to sharpen your skills or a newcomer eager to learn the ropes, this article will provide you with valuable insights and practical tips to take your metalworking projects to the next level. From understanding the importance of turning inserts to honing your technique, join us on this journey to elevate your craftsmanship and achieve superior results in the world of metalworking.

- Understanding the Basics of Metalworking Inserts

Metalworking inserts play a crucial role in the process of precision metalworking, particularly in turning operations. Understanding the basics of metalworking inserts is essential for anyone looking to master the art of precision in this field. In this comprehensive guide, we will delve into the intricacies of turning inserts in metalworking.

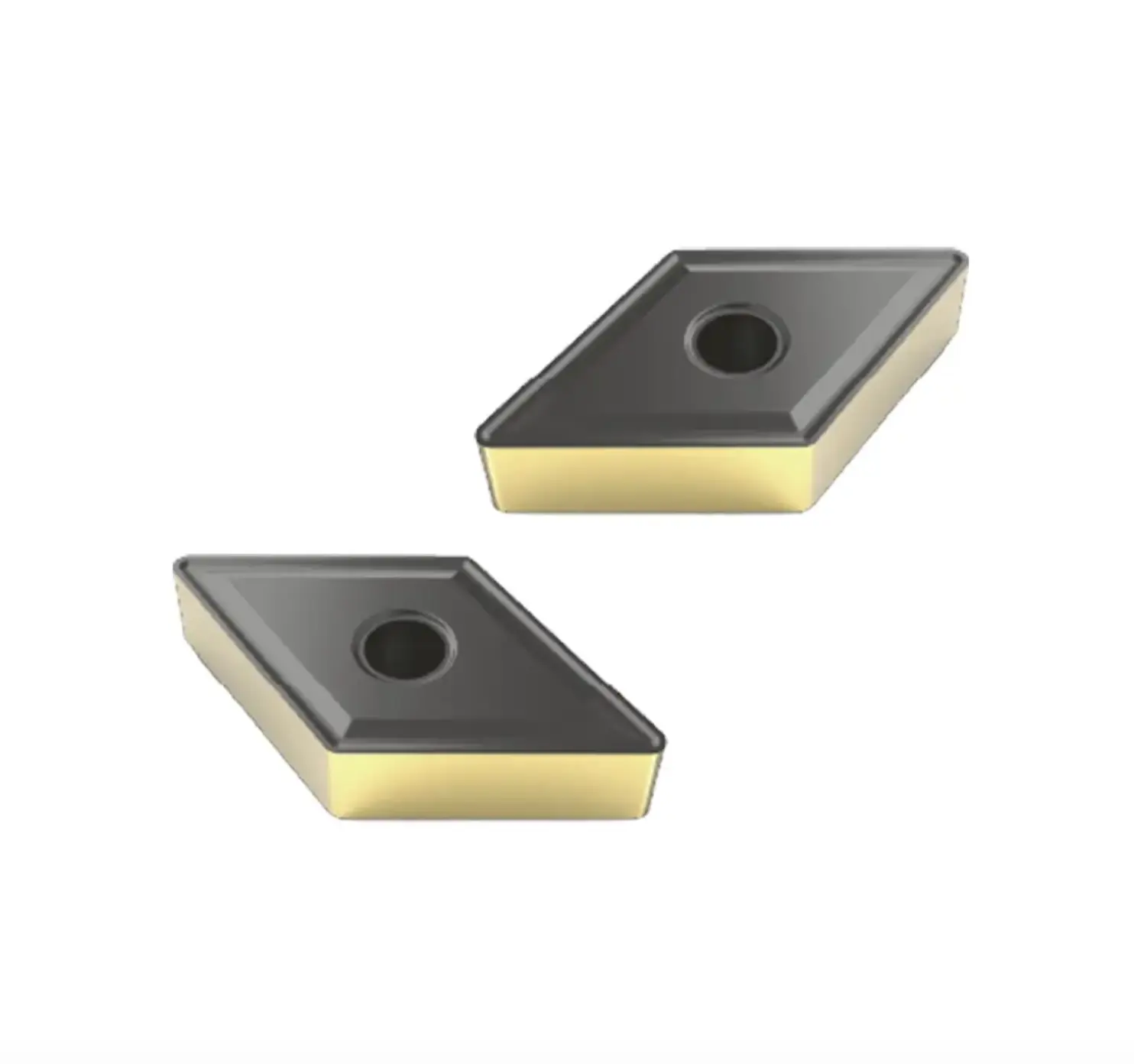

What are turning inserts? Turning inserts are cutting tools that are used in lathes to remove material from a workpiece. They are typically made of carbide, cermet, ceramic, or other cutting materials, and are designed to withstand the high temperatures and pressures generated during the machining process. Turning inserts come in a variety of shapes and sizes, each designed for specific types of cuts and materials.

There are several factors to consider when selecting the right turning insert for a particular application. These include the material being machined, the speed and feed rates of the cutting tool, and the desired surface finish. Choosing the right insert can make a significant difference in the efficiency and accuracy of the machining process.

One of the key advantages of using turning inserts in metalworking is their ability to provide consistent and precise cuts. The geometry and material composition of the insert are carefully engineered to ensure optimal performance and longevity. This allows for greater control over the machining process and the ability to achieve tight tolerances and high-quality surface finishes.

In addition to their precision, turning inserts offer increased productivity and cost-effectiveness. By using inserts that can be easily replaced when worn out, machining downtime is minimized, and overall production efficiency is improved. This results in lower costs and higher output for manufacturers.

To maximize the performance of turning inserts, it is essential to follow proper maintenance and care procedures. Regularly inspecting inserts for wear and damage, as well as ensuring proper coolant and cutting conditions, can help extend the life of the inserts and improve overall machining efficiency.

In conclusion, mastering the art of precision in metalworking requires a thorough understanding of turning inserts. By selecting the right insert for the job, maintaining proper cutting conditions, and following best practices for insert care, manufacturers can achieve superior results in their machining operations. With the right knowledge and attention to detail, turning inserts can be a valuable tool for achieving high-quality, cost-effective metalworking outcomes.

- Selecting the Right Tools for Precision Turning

In the world of metalworking, precision turning is a crucial process that requires the right tools to achieve accurate and high-quality results. One of the key components in precision turning is the use of turning inserts, which play a vital role in shaping and finishing metal components. Selecting the right tools for precision turning is essential for achieving the desired results and minimizing errors in the machining process.

Turning inserts are cutting tools that are used in lathes or turning machines to remove material from a workpiece. These inserts are typically made from hard materials such as carbide, ceramic, or diamond, and come in a variety of shapes and sizes to suit different machining applications. The choice of turning inserts depends on factors such as the material being machined, the cutting speed and feed rate, and the desired surface finish.

When selecting turning inserts for precision turning, it is important to consider the material being machined. Different materials have different hardness and cutting characteristics, so it is important to choose inserts that are suitable for the specific material. For example, carbide inserts are commonly used for machining steel and other ferrous metals, while ceramic inserts are preferred for machining heat-resistant alloys and other difficult-to-machine materials.

In addition to material considerations, the cutting speed and feed rate also play a crucial role in selecting the right turning inserts. The cutting speed refers to the speed at which the cutting tool moves across the workpiece, while the feed rate refers to the depth of cut per revolution. It is important to choose inserts that can withstand the high cutting speeds and feed rates required for precision turning without chipping or breaking.

Another important factor to consider when selecting turning inserts is the desired surface finish. Inserts with sharper cutting edges and smaller cutting angles are ideal for achieving a smooth surface finish, while inserts with larger cutting angles are better suited for roughing and heavy material removal. By choosing the right inserts for the desired surface finish, machinists can achieve the precision and quality required for their metal components.

In conclusion, mastering the art of precision turning requires careful consideration and selection of the right tools, particularly turning inserts. By taking into account factors such as material, cutting speed, feed rate, and surface finish, machinists can achieve accurate and high-quality results in their metalworking projects. With the right tools and techniques, precision turning can be a highly effective and efficient process in producing parts and components with tight tolerances and superior surface finishes.

- Techniques for Achieving Consistent and Accurate Inserts

Mastering the Art of Precision: A Guide to Turning Inserts in Metalworking - Techniques for Achieving Consistent and Accurate Inserts

In the world of metalworking, achieving precise and consistent turning inserts is a fundamental aspect of the craft. It is an art that requires not only skill and expertise but also an understanding of the techniques involved. This guide aims to delve into the intricacies of turning inserts, focusing on techniques that enable metalworkers to achieve consistent and accurate results. By mastering these techniques, artisans in the field can elevate their craftsmanship and produce exceptional pieces with precision and finesse.

Understanding Turning Inserts:

Turning inserts are cutting tools used in metalworking to shape and mold various materials. They are crucial in creating cylindrical shapes, such as cylinders, cones, and tapers, through the process of turning. These inserts are typically made from carbide, ceramics, or other hard materials, ensuring durability and longevity. Achieving consistent and accurate turning inserts is essential for metalworkers, as it directly impacts the overall quality and functionality of the finished product.

Techniques for Consistent Turning Inserts:

1. Tool Selection:

Selecting the appropriate turning insert is the first step towards achieving consistency and accuracy. Different projects require different types of inserts, depending on factors such as material, depth of cut, and desired finish. It is crucial to consider the geometry, cutting edge angle, and coating of the insert to ensure optimal performance.

2. Rigidity and Stability:

Maintaining rigidity and stability during the turning process is vital for obtaining consistent results. This can be achieved by using a sturdy lathe machine and securing the workpiece firmly. Minimizing vibrations and rigidly clamping the tool holder are also crucial to reduce any deviation in the turning insert's path.

3. Cutting Speed and Feed Rate:

Finding the right balance between cutting speed and feed rate plays a significant role in achieving accuracy and consistency. Higher cutting speeds can result in a smoother finish, but it is essential to ensure the tool's strength and stability to withstand the forces involved. Similarly, the feed rate must be adjusted to match the cutting speed and material to avoid tool wear.

4. Tool Geometry:

The geometry of the turning insert greatly affects the precision and consistency of the outcome. Factors such as nose radius, rake angle, and clearance angle must be carefully considered. Optimal geometry helps in minimizing cutting forces, reducing heat generation, and extending tool life.

5. Lubrication and Cooling:

Proper lubrication and cooling are essential to prevent heat build-up and maintain the integrity of the turning insert. Using appropriate cutting fluids or coolants can enhance tool life and improve chip control, ensuring consistent and accurate turning inserts.

6. Quality Control:

Implementing effective quality control measures is crucial for achieving consistent and accurate turning inserts. Regularly inspecting and measuring the inserts' dimensions, surface finish, and flank wear allow metalworkers to identify any issues promptly. This enables adjustments to be made, ensuring that the inserts meet the required specifications.

Mastering the art of precision in metalworking involves understanding and employing techniques for achieving consistent and accurate turning inserts. From selecting the right tools and maintaining rigidity to considering cutting speed and feed rate, each step is crucial in producing exceptional results. By implementing these techniques and incorporating strict quality control measures, metalworkers can elevate their craftsmanship and master the intricacies of turning inserts, ultimately producing superior pieces with precision and finesse.

- Troubleshooting Common Issues in Metalworking

In the world of metalworking, mastering the art of precision is essential for achieving high-quality results. One key aspect of metalworking is the use of turning inserts, which are cutting tools that are used to remove material from a workpiece. Turning inserts come in a variety of shapes and sizes, each designed for specific types of machining operations.

When it comes to using turning inserts in metalworking, there are several common issues that can arise. Understanding how to troubleshoot these issues can help ensure that you achieve optimal results in your machining operations.

One common issue that metalworkers may encounter when using turning inserts is poor surface finish. This can be caused by a number of factors, including incorrect cutting parameters, worn-out inserts, or inadequate lubrication. To troubleshoot this issue, it is important to first check the cutting parameters to ensure that they are appropriate for the material being machined. Additionally, inspect the turning inserts for signs of wear and replace them if necessary. Finally, make sure that the workpiece is properly lubricated to reduce friction and improve surface finish.

Another common issue that metalworkers may face when using turning inserts is chatter. Chatter is a vibration that occurs during cutting, which can lead to poor surface finish and tool wear. Chatter can be caused by a number of factors, including improper tooling setup, insufficient rigidity in the machining setup, or incorrect cutting parameters. To troubleshoot chatter, it is important to first ensure that the tooling setup is correct and that the machining setup is rigid. Additionally, adjusting the cutting parameters, such as feed rate and cutting speed, can help reduce chatter and improve machining results.

Tool breakage is another common issue that metalworkers may encounter when using turning inserts. Tool breakage can occur due to factors such as excessive cutting forces, incorrect tooling setup, or inadequate tool material. To troubleshoot tool breakage, it is important to first check the cutting forces and adjust the cutting parameters if necessary. Additionally, inspect the tooling setup to ensure that it is correct and make sure that the turning inserts are made from a durable material that can withstand the forces of machining.

In conclusion, mastering the art of precision in metalworking requires a thorough understanding of turning inserts and the common issues that can arise when using them. By troubleshooting issues such as poor surface finish, chatter, and tool breakage, metalworkers can achieve optimal results in their machining operations. With the right knowledge and techniques, turning inserts can be a valuable tool for producing high-quality metal parts.

- Tips for Advancing Your Skills in Precision Turning

Mastering the art of precision in metalworking is a crucial skill that can set you apart in the industry. One of the key components of achieving this level of precision is through the use of turning inserts. In this comprehensive guide, we will delve into the tips and techniques for advancing your skills in precision turning, focusing specifically on how to properly utilize turning inserts to achieve the desired results.

Turning inserts are crucial tools in metalworking, as they are responsible for shaping and finishing the surface of the workpiece. These inserts come in a variety of shapes, sizes, and materials, each tailored to specific applications. By understanding the different types of turning inserts available, you can optimize your turning process and achieve greater precision in your work.

One of the first tips for advancing your skills in precision turning is to choose the right turning insert for the job. When selecting a turning insert, consider factors such as material composition, coating, and geometry. For example, carbide inserts are ideal for high-speed cutting, while ceramic inserts are better suited for high-temperature applications. By choosing the appropriate turning insert for the task at hand, you can improve the efficiency and accuracy of your turning operations.

Another key tip for advancing your skills in precision turning is to properly prepare and set up your turning insert. Before inserting the tool into the holder, ensure that the insert is clean and free from any defects or damage. Additionally, make sure to align the insert correctly in the holder to ensure optimal cutting performance. Proper setup and alignment of the turning insert are essential for achieving consistent and accurate results in your turning operations.

Once your turning insert is properly set up, it is crucial to pay attention to cutting parameters such as cutting speed, feed rate, and depth of cut. By optimizing these parameters based on the material being cut and the desired surface finish, you can achieve precise and efficient turning results. Experiment with different cutting parameters to find the optimal balance between speed and tool life, ultimately leading to improved precision in your turning operations.

In addition to selecting the right turning insert and optimizing cutting parameters, it is important to regularly monitor and maintain your turning inserts. Inspect the inserts for wear and damage, and replace them as needed to ensure consistent cutting performance. Proper maintenance of turning inserts will not only extend their lifespan but also improve the quality and accuracy of your workpieces.

In conclusion, mastering the art of precision in metalworking requires a combination of skill, knowledge, and attention to detail. By following the tips and techniques outlined in this guide, you can advance your skills in precision turning and achieve better results in your metalworking projects. Remember to choose the right turning insert, properly prepare and set up the tool, optimize cutting parameters, and maintain the inserts regularly to ensure maximum precision in your turning operations. With practice and dedication, you can become a master of precision turning and elevate your metalworking skills to new heights.

Conclusion

In conclusion, mastering the art of precision in metalworking is crucial for achieving top-quality results. By following the guide to turning inserts provided in this article, metalworkers can effectively enhance their skills and produce well-crafted pieces with accuracy and finesse. Remember that practice makes perfect, so don't be afraid to experiment and refine your techniques. With dedication and patience, you can soon become a master in the art of precision metalworking. Keep pushing the boundaries of your craft and never stop striving for excellence. Happy turning!