CVD Coated Inserts: Features And Uses In Metal Cutting

Welcome to our comprehensive guide to CVD coated inserts and their myriad features and uses in metal cutting applications. In this article, we will delve into the world of cutting tools and explore the advantages and applications of CVD coated inserts. Whether you are a seasoned professional or newcomer to the world of metal cutting, this article will provide valuable insights into the benefits of CVD coated inserts and how they can enhance your machining processes. Join us as we uncover the key features and uses of CVD coated inserts and how they can revolutionize the way you approach metal cutting.

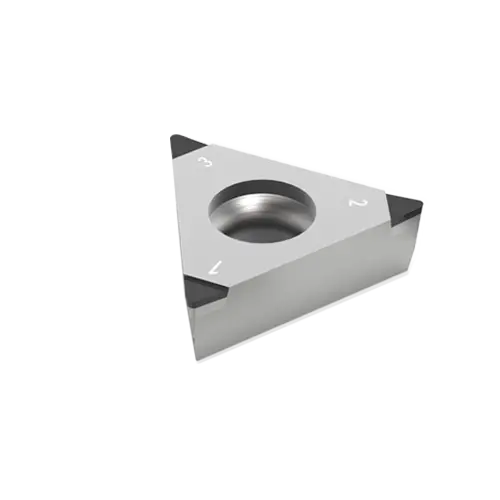

CVD Coated Inserts: Features and Uses in Metal Cutting

CVD (Chemical Vapor Deposition) coated inserts are a popular choice for metal cutting applications due to their exceptional durability and performance. In this article, we will explore the features and uses of CVD coated inserts, as well as their benefits in metal cutting processes.

1. Understanding CVD Coating Technology

CVD coating is a process in which a thin film of a desired material is deposited onto a substrate through chemical reactions in a controlled environment. In the case of CVD coated inserts, the substrate is typically made of a hard material such as carbide, which is commonly used in cutting tools due to its high hardness and wear resistance.

The CVD coating applied to the inserts is often comprised of various carbides, nitrides, and other hard materials that provide the inserts with superior wear resistance, high thermal stability, and low friction properties. This ultimately results in longer tool life, improved surface finish, and extended cutting speeds and feeds.

2. Features of CVD Coated Inserts

CVD coated inserts offer several key features that make them highly desirable for metal cutting applications. Some of these features include:

- High hardness and wear resistance: The CVD coating significantly increases the hardness and wear resistance of the inserts, making them capable of withstanding the high temperatures and abrasive forces encountered during metal cutting.

- Thermal stability: The CVD coating provides thermal stability to the inserts, allowing them to maintain their cutting edge integrity even at elevated temperatures, which is crucial for achieving consistent and accurate machining results.

- Low friction: The low friction properties of CVD coated inserts help reduce heat build-up and chip welding, resulting in improved surface finish and reduced cutting forces.

- Versatility: CVD coated inserts can be used for a wide range of metal cutting applications, including turning, milling, drilling, and grooving, making them a versatile choice for various machining operations.

3. Uses of CVD Coated Inserts in Metal Cutting

CVD coated inserts are commonly used in metal cutting processes involving materials such as steel, stainless steel, cast iron, and high-temperature alloys. They are particularly well-suited for high-speed machining, interrupted cutting, and hard material machining, where the cutting tool is subjected to severe mechanical and thermal loads.

These inserts are often employed in the automotive, aerospace, energy, and general engineering industries, where the demand for high precision and productivity in metal cutting operations is paramount. Whether it's high-speed turning of stainless steel components or heavy-duty milling of cast iron parts, CVD coated inserts have proven to be a reliable and efficient solution for these applications.

4. Benefits of Using CVD Coated Inserts

The use of CVD coated inserts in metal cutting offers several significant benefits, including:

- Extended tool life: CVD coated inserts have a longer lifespan compared to uncoated inserts, reducing the frequency of tool changes and downtime in machining operations.

- Increased productivity: The enhanced wear resistance and thermal stability of CVD coated inserts allow for higher cutting speeds and feeds, leading to improved machining efficiency and throughput.

- Improved surface finish: The low friction properties of CVD coated inserts contribute to superior surface finish quality, reducing the need for secondary finishing operations and enhancing the overall part quality.

- Cost savings: By reducing tooling expenses, increasing machining efficiency, and minimizing the need for additional finishing processes, CVD coated inserts help lower the overall production costs for metal cutting operations.

5.

CVD coated inserts have become an indispensable tooling solution for metal cutting applications, offering exceptional wear resistance, thermal stability, and versatility. With their ability to prolong tool life, enhance productivity, and improve surface finish quality, CVD coated inserts have earned a reputation as a cost-effective and reliable choice for manufacturers seeking to optimize their machining processes.

As an industry-leading provider of cutting tools and inserts, VeryCarbon is committed to delivering high-quality CVD coated inserts that meet the diverse needs of our customers in metal cutting applications. Our advanced CVD coating technology, combined with precision engineering and stringent quality control, ensures that our CVD coated inserts deliver superior performance, durability, and value to our customers across various industries. With VeryCarbon CVD coated inserts, you can expect nothing less than exceptional cutting performance and efficiency in your metal cutting operations.

Conclusion

In conclusion, CVD coated inserts offer a wide range of benefits and advantages in metal cutting processes. From their high wear resistance to their ability to improve tool life and increase cutting speeds, these inserts are a valuable tool for manufacturers and machinists alike. With their ability to withstand high temperatures and provide superior surface finish, CVD coated inserts have become a popular choice for a variety of metal cutting applications. Whether used in turning, milling, or drilling operations, these inserts offer superior performance, making them a valuable asset in the metalworking industry. As technology continues to advance, we can expect to see further innovations and developments in CVD coated inserts, further improving their features and uses in metal cutting.